Sealing Australia stocks a comprehensive range of hydraulic and pneumatic seals.

Sealing Australia are distributors of SKF Fluid Power Seals. SKF’s state-of-the-art materials, production capabilities and R&D place them at the forefront of sealing technology and Sealing Australia are proud to have them on board.

Fluid power systems transfer and utilise mechanical power through a working fluid. Energy is transmitted, stored and used through the transfer and pressure of fluids. By utilising differential surface areas acted upon by the pressure of the working fluid, a mechanical advantage can be achieved. There are two main types of fluid power systems:

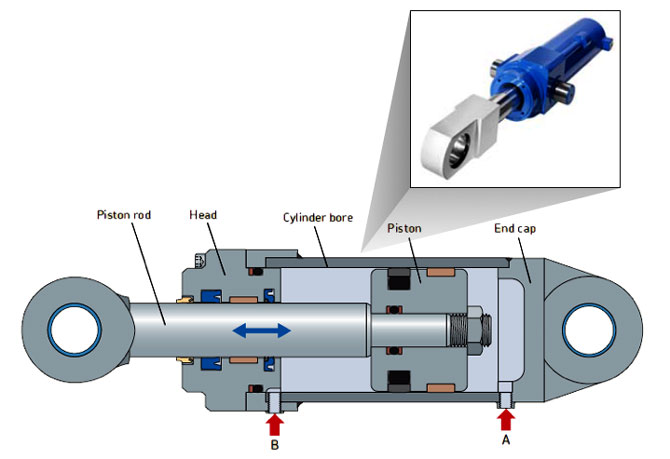

A hydraulic cylinder is a linear actuator used to push or pull a load, or to selectively resist motion under load by means of fluid pressure. Double-acting cylinders, the most common type, are able to push and pull (see Fig.1). High pressure fluid is pumped into the extend chamber port (Fig.1: A) and acts on the piston to push the piston rod out, thereby extending the length of the cylinder. Inversely, to retract the piston rod and reduce the length of the assembly, high pressure fluid is pumped into the retract chamber port (Fig.1: B) and acts on the opposite side of the piston.

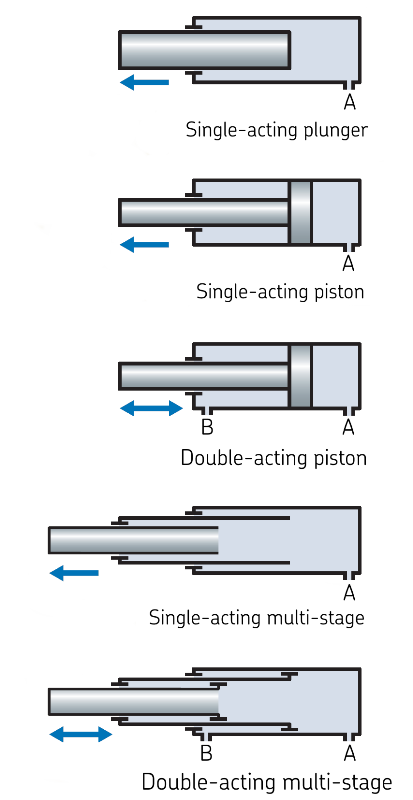

A cylinder which can only push but not pull is referred to as a single-acting cylinder. High pressure fluid is pumped into the extend chamber (Fig.2: A) and acts on the piston to push the piston rod out. An external force is required to return the cylinder to the retracted position. A typical single-acting cylinder can be found on a forklift truck where the load of the fork assembly (tines and carriage) enacted by gravity pushes the cylinder back into the retracted position. Multi-stage cylinders (also referred to as telescopic cylinders) have two or more piston rods in a coaxial arrangement to achieve a greater extended length compared to the retracted length.

The type of cylinder and the application in which it’s used are two of the main criteria to determine which seals and guides are selected. Applications are referred to as light duty, medium duty and heavy duty. These classifications are somewhat subjective but the duty levels are typically characterised by the following criteria.

Light duty cylinders are typically cylinders used for stationary equipment, indoors in a factory environment and may be characterised by:

Medium duty cylinders are typically used in agriculture, off-highway equipment and may be characterised by:

Heavy duty cylinders are typically used in off-highway earthmoving, mining and forestry equipment and may be characterised by:

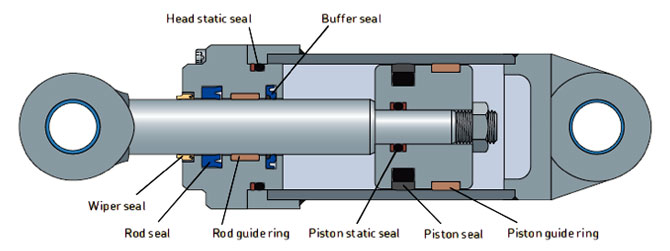

Hydraulic cylinder seals are used to seal the opening (clearance gap) between various components in the hydraulic cylinder. Fig.3 shows an example of the seal and guide components of a heavy duty cylinder.

There are two main types of hydraulic seals in the system:

Materials play a major role in the performance and lifetime of seals. Generally, hydraulic seals are exposed to a variety of application and working conditions such as a wide temperature range, contact with various hydraulic fluids and the outside environment as well as high pressure and contact forces. The appropriate seal materials have to be selected to achieve a reasonable service life and service intervals. A wide variety of seal materials from four major polymeric material groups is available:

Polyurethanes combine the elastic properties of elastomers with melt processible thermoplastic materials. Seals made of polyurethanes provide excellent wear and anti-extrusion characteristics. Special sealing polyurethanes grades have a superior compression set and relaxation performance as well as temperature stability compared to commodity industrial grades. Due to their elasticity and flexibility, they are easy to install.

Rubbers are widely used in the sealing industry for rotary shaft seals, static sealing elements such as o’rings and energisers as well as dynamic seals in the fluid power industry. Depending on the chemical composition, rubbers can cover a wide temperature range up to 200°C (390°F) and more and can withstand a wide variety of hydraulic fluids. NBR elastomer in a hardness range of 70 to 90 Shore A Durometer are the most commonly used rubbers in the fluid industry. For higher temperatures and more aggressive hydraulic fluids, HNBR and FKM material is often used.

Often referred to its DuPont trade name Teflon, PTFE is a polymer with very unique properties. Due to its chemical composition and physiologically neutral properties, it is a plastic material with a very broad range of chemical resistance and very low coefficient of friction; however it has some restrictions in terms of mechanical properties and wear characteristics. Therefore PTFE is often modified by adding various fillers to improve specific properties such as wear or extrusion resistance. One important characteristic of PTFE is the low friction coefficient giving outstanding stick-slip performance. Therefore PTFE is the preferred material in applications requiring accurate positioning of hydraulic cylinders. Due to increased modulus of elasticity compared to rubbers and polyurethanes, PTFE seals cannot usually be installed by simple snap-in measures therefore require special tools and procedures for installation.

Rigid Thermoplastics, thermosets and their composites are characterised by much higher hardness and stiffness as well as reduced elasticity compared to polyurethanes, rubbers and PTFE. Therefore they’re used for components where mechanical strength is more important than flexibility, such as guide rings, anti-extrusion rings and special seal arrangements for heavy duty applications. Rigid thermoplastics and composites.

To support sealing function and keep the contact force for long seal life, many different properties should be considered to provide effective seal performance, examples include:

In addition to these considerations, the structure and morphology (the study of form and shape) of polymeric materials make selection and specification of seal materials much more complicated than the standard materials used in mechanical engineering (such as aluminium and steel). Mechanical properties of polymeric materials are strongly influenced by time, temperature, load and rate of motion. Highly complex intermolecular processes affect the stress relaxation and retardation phenomena. Furthermore, the tribology of the system (e.g. friction and wear) has a strong influence on the seal material properties and vice versa.

Fluids in hydraulic systems serve multiple functions for system performance:

The fluids used in hydraulic systems come in various chemical compositions and viscosity grades as suited to specific applications.

Viscosity is a measurement of the thickness of the fluid or resistance to flow. Seal performance is affected by the viscosity of the fluid and changes to viscosity during use. Most typical hydraulic fluids exhibit decreased viscosity with increasing temperature and increased viscosity with increasing pressure.

The most commonly used media in hydraulic systems are mineral oil based fluids with various additives. However, a variety of alternative fluids may be encountered in special applications. For example, biodegradable fluids such as synthetic (HEES) or natural esters (HETG) and polyalphaolefines (POA) may be used to reduce environmental impact in the event of accidental spills. Flame retardant fluids based on water or synthetic esters may be safely used in confined spaces or where hydraulic systems are used in close proximity to ignition sources.

The chemical composition on hydraulic fluids can impact the seal life and system performance depending on fluid compatibility with the seal material. Absorption and reaction of seal materials with non-compatible fluids can cause for example:

Generally these changes are accelerated by higher temperatures. To avoid these changes and the resulting damage to seal function and life, careful consideration should be taken to ensure compatibility between fluid and all seal materials, as well as the temperature and mechanical loads on the seal material.

The following table is a guide for seal materials and their compatibility with common grades of hydraulic fluids.

| Thermoplastic Elastomers | Rubbers | Thermosets | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | Polyurethane | Polyurethane | Hydrolysis Resistant Polyurethane | Hydrolysis Resistant Polyurethane | Ether-Based TPU | Ether-Based TPU | Polyester | Polyester | NBR/HNBR | NBR/HNBR | FKM | FKM | EPDM | PA/PF | PM | PEEK | PTFE |

| Temperature | Normal | High | Normal | High | Normal | High | Normal | High | Normal | High | Normal | High | All | All | All | All | All |

| Hydraulic Fluids | Up to 60°C | Up to 100°C | Up to 60°C | Up to 100°C | Up to 60°C | Up to 100°C | Up to 60°C | Up to 100°C | Up to 60°C | Up to 100°C | Up to 60°C | Up to 100°C | |||||

| Mineral Oils HL, HLP, HVLP | A | B | A | A | A | B/C | A | A/B | A | A | A | A | D | A | A | A | A |

| ATF: Automatic transmission fluid | A | B | A | A | A | B/C | A | B | A | A | A | A | D | A | A | A | A |

| HETG (triglycerides, rape seed oil) | A | B/C | A | A | A | C | A | B/C | A/B | A/B | A | A | D | A | A | A | A |

| HEES (synthetic esters) | A | B/C | A | A | A | C | A | B/C | A/B | A/B | A | A | D | A | A | A | A |

| HEPG (polyalkylene glycols) | B | D | A | C | B/C | D | C | D | A | A/B | A/B | C/D | A | A | A | A | A |

| HEPR (polyalphaolefins) | A | B | A | A | A | B/C | A | B | A/B | A/B | A | A | D | A | A | A | A |

| Fire Resistant Fluids, Water Based | Up to 40°C | Up to 60°C | Up to 40°C | Up to 60°C | Up to 40°C | Up to 60°C | Up to 40°C | Up to 60°C | Up to 40°C | Up to 60°C | Up to 40°C | Up to 60°C | |||||

| Water | B | D | A | A | A | B | A | B | A | A | A | A | A | C | A | A | A |

| HFA Fluids (oil in water) | B | D | A | A | B | B/C | A | B | A | A | A | B | D | C | A | A | A |

| HFB Fluids (water in oil) | B | D | A | A | B | D | A | B | A | A | A | A | D | C | A | A | A |

| HFC Fluids (water – glycol) | C | D | A | B/C | B | B/C | C | D | A | A | A/B | B/C | A | C | A | A | A |

| Fire Resistant Fluids, Water Free | Up to 60°C | Up to 100°C | Up to 60°C | Up to 100°C | Up to 60°C | Up to 100°C | Up to 60°C | Up to 100°C | Up to 60°C | Up to 100°C | Up to 60°C | Up to 100°C | |||||

| HFD-R Fluids | D | D | D | D | D | D | D | D | D | D | C | C | A | A | A | A | A |

| HFD-U Fluids (polyol amd carboxylic esters) | B | D | A | A | B | D | A | B/C | C | C | A | A | D | A | A | A | A |

| Mineral Greases | A | B | A | A | A | B | A | A | A | A | A | A | D | A | A | A | A |

HOURS OF OPERATION • AEST Monday to Thursday 8.30 am – 5.30 pm