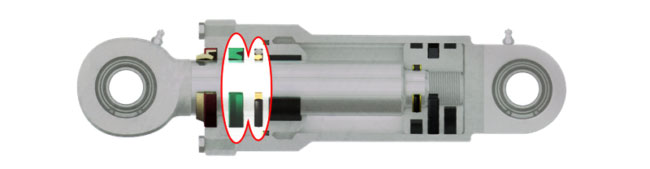

Rod seals are typically single-acting seals, which means fluid pressure acts from inside the cylinder on one side of the seal only. Buffer seals protect the rod seals by reducing pressure peaks (sudden pressure spikes).

Rod seals are typically single-acting seals, which means fluid pressure acts from inside the cylinder on one side of the seal only. Pressures acting on the rod side of the seal can be in excess of 400 bar (5,800 psi), pressure peaks can be even higher. The pressure acting on the rod seal increases contact forces between the rod seal and cylinder surfaces. Therefore, rod seal materials should be wear resistant and the rod surface needs to be manufactured to the recommended specifications.

Buffer seals protect the rod seals by reducing pressure peaks (sudden pressure spikes). Abrupt pressure peaks can occur by external forces acting on the piston rod initiated by the fluid inside the cylinder. These pressure peaks can be far in excess of the system operating pressure. Buffer seals in combination with rod seals provide an effective rod sealing system for cylinders in heavy duty applications at high temperature and pressure.

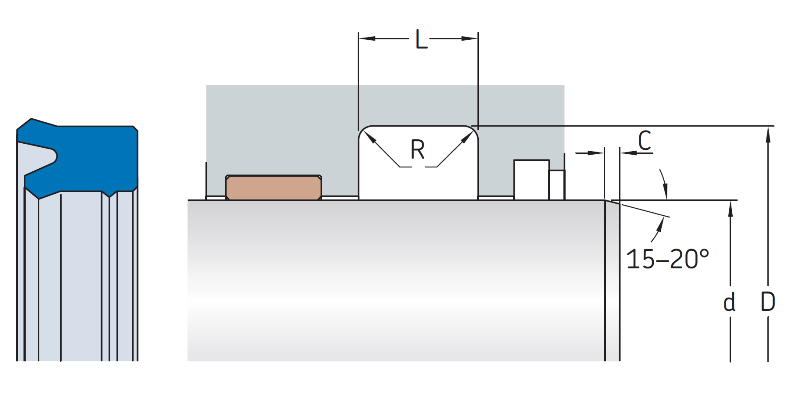

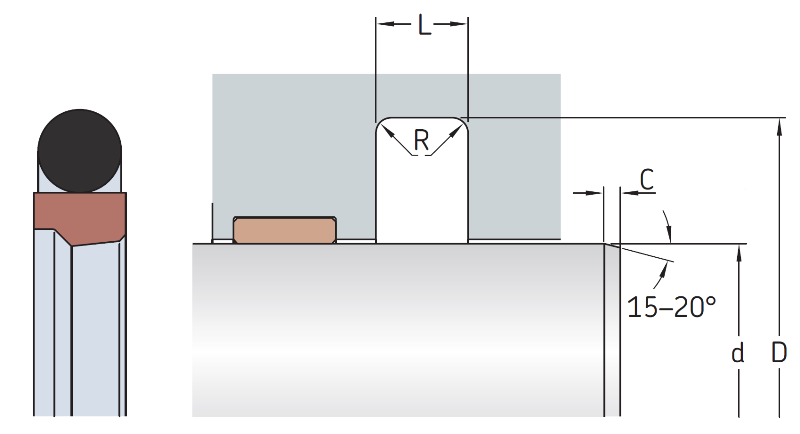

SIL profiles are made of ether based polyurethane and have a double lip design. They provide good resistance to hydrolysis (attack from moisture) and good low temperature resilience. These profiles are suitable for pressures up to 350 bar (5,075 psi) for light to medium duty applications and are available in metric sizes only.

| Part No | (d) ±h9 | (D) ±H9 | (L) +0.2 | (R) max | (C) min |

|---|---|---|---|---|---|

| SIL 10*18*6.3 | 10.0 | 18.0 | 6.3 | 0.3 | 2.0 |

| SIL 12*20*6.3 | 12.0 | 20.0 | 6.3 | 0.3 | 2.0 |

| SIL 12*22*8 | 12.0 | 22.0 | 8.0 | 0.3 | 2.5 |

| SIL 14*22*6.3 | 14.0 | 22.0 | 6.3 | 0.3 | 2.0 |

| SIL 14*24*8 | 14.0 | 24.0 | 8.0 | 0.3 | 2.0 |

| SIL 16*22*6 | 16.0 | 22.0 | 6.0 | 0.3 | 2.0 |

| SIL 16*24*6.3 | 16.0 | 24.0 | 6.3 | 0.3 | 2.0 |

| SIL 16*24*7 | 16.0 | 24.0 | 7.0 | 0.3 | 2.0 |

| SIL 18*24*5.2 | 18.0 | 24.0 | 5.2 | 0.3 | 2.0 |

| SIL 18*26*6.3 | 18.0 | 26.0 | 6.3 | 0.3 | 2.0 |

| SIL 20*26*5.5 | 20.0 | 26.0 | 5.5 | 0.3 | 2.0 |

| SIL 20*28*6.3 | 20.0 | 28.0 | 6.3 | 0.3 | 2.0 |

| SIL 20*30*8 | 20.0 | 30.0 | 8.0 | 0.3 | 2.5 |

| SIL 20*30*9 | 20.0 | 30.0 | 9.0 | 0.3 | 2.5 |

| SIL 22*30*6.3 | 22.0 | 30.0 | 6.3 | 0.3 | 2.0 |

| SIL 22*32*8 | 22.0 | 32.0 | 8.0 | 0.3 | 2.5 |

| SIL 25*33*6.3 | 25.0 | 33.0 | 6.3 | 0.3 | 2.0 |

| SIL 25*33*7 | 25.0 | 33.0 | 7.0 | 0.3 | 2.0 |

| SIL 25*33*11 | 25.0 | 33.0 | 11 | 0.3 | 2.0 |

| SIL 25*35*8 | 25.0 | 35.0 | 8.0 | 0.3 | 2.5 |

| SIL 25*35*9 | 25.0 | 35.0 | 9.0 | 0.3 | 2.5 |

| SIL 25*35*11 | 25.0 | 35.0 | 11.0 | 0.3 | 2.5 |

| SIL 28*38*8 | 28.0 | 38.0 | 8.0 | 0.3 | 2.5 |

| SIL 28*38*9 | 28.0 | 38.0 | 9.0 | 0.3 | 2.5 |

| SIL 28*43*12.5 | 28.0 | 43.0 | 12.5 | 0.4 | 4.0 |

| SIL 30*38*6.3 | 30.0 | 38.0 | 6.3 | 0.3 | 2.0 |

| SIL 30*40*8 | 30.0 | 40.0 | 8.0 | 0.3 | 2.5 |

| SIL 30*40*11 | 30.0 | 40.0 | 11.0 | 0.3 | 2.5 |

| SIL 30*45*11 | 30.0 | 45.0 | 11.0 | 0.4 | 4.0 |

| SIL 32*40*6.3 | 32.0 | 40.0 | 6.3 | 0.3 | 2.0 |

| SIL 32*40*9 | 32.0 | 40.0 | 9.0 | 0.3 | 2.0 |

| SIL 32*42*8 | 32.0 | 42.0 | 8.0 | 0.3 | 2.5 |

| SIL 32*42*11 | 32.0 | 42.0 | 11.0 | 0.3 | 2.5 |

| SIL 32*47*12.5 | 32.0 | 47.0 | 12.5 | 0.4 | 4.0 |

| SIL 33*43*11 | 33.0 | 43.0 | 11.0 | 0.3 | 2.5 |

| SIL 35*43*6.3 | 35.0 | 43.0 | 6.3 | 0.3 | 2.0 |

| SIL 35*45*8 | 35.0 | 45.0 | 8.0 | 0.3 | 2.5 |

| SIL 35*45*11 | 35.0 | 45.0 | 11.0 | 0.3 | 2.5 |

| SIL 35*50*11 | 35.0 | 50.0 | 11.0 | 0.4 | 4.0 |

| SIL 36*44*7 | 36.0 | 44.0 | 7.0 | 0.3 | 2.0 |

| SIL 36*46*8 | 36.0 | 46.0 | 8.0 | 0.3 | 2.5 |

| SIL 36*51*12.5 | 36.0 | 51.0 | 12.5 | 0.4 | 4.0 |

| SIL 40*50*8 | 40.0 | 50.0 | 8.0 | 0.3 | 2.5 |

| SIL 40*50*11 | 40.0 | 50.0 | 11.0 | 0.3 | 2.5 |

| SIL 40*55*11 | 40.0 | 55.0 | 11.0 | 0.4 | 4.0 |

| SIL 40*55*12.5 | 40.0 | 55.0 | 12.5 | 0.4 | 4.0 |

| SIL 40*60*13 | 40.0 | 60.0 | 13.0 | 0.6 | 5.0 |

| SIL 42*52*11 | 42.0 | 52.0 | 11.0 | 0.3 | 2.5 |

| SIL 45*55*8 | 45.0 | 55.0 | 8.0 | 0.3 | 2.5 |

| SIL 45*55*11 | 45.0 | 55.0 | 11.0 | 0.3 | 2.5 |

| SIL 45*60*11 | 45.0 | 60.0 | 11.0 | 0.4 | 4.0 |

| SIL 45*60*12.5 | 45.0 | 60.0 | 12.5 | 0.4 | 4.0 |

| SIL 46*56*11 | 46.0 | 56.0 | 11.0 | 0.3 | 2.5 |

| SIL 50*60*8 | 50.0 | 60.0 | 8.0 | 0.3 | 2.5 |

| SIL 50*60*11 | 50.0 | 60.0 | 11.0 | 0.3 | 2.5 |

| SIL 50*65*11 | 50.0 | 65.0 | 11.0 | 0.4 | 4.0 |

| SIL 50*65*12.5 | 50.0 | 65.0 | 12.5 | 0.4 | 4.0 |

| SIL 55*65*11 | 55.0 | 65.0 | 11.0 | 0.3 | 2.5 |

| SIL 55*70*12.5 | 55.0 | 70.0 | 12.5 | 0.4 | 4.0 |

| SIL 56*71*11 | 56.0 | 71.0 | 11.0 | 0.4 | 4.0 |

| SIL 56*71*12.5 | 56.0 | 71.0 | 12.5 | 0.4 | 4.0 |

| SIL 56*76*16 | 56.0 | 76.0 | 16.0 | 0.6 | 5.0 |

| SIL 60*70*11 | 60.0 | 70.0 | 11.0 | 0.3 | 2.5 |

| SIL 60*70*13 | 60.0 | 70.0 | 13.0 | 0.3 | 2.5 |

| SIL 60*75*11 | 60.0 | 75.0 | 11.0 | 0.4 | 4.0 |

| SIL 60*75*13 | 60.0 | 75.0 | 13.0 | 0.4 | 4.0 |

| SIL 63*73*13 | 63.0 | 73.0 | 13.0 | 0.3 | 2.5 |

| SIL 63*78*11 | 63.0 | 78.0 | 11.0 | 0.4 | 4.0 |

| SIL 63*78*12.5 | 63.0 | 78.0 | 12.5 | 0.4 | 4.0 |

| SIL 63*83*13 | 63.0 | 83.0 | 13.0 | 0.6 | 5.0 |

| SIL 63*83*16 | 63.0 | 83.0 | 16.0 | 0.6 | 5.0 |

| SIL 65*75*13 | 65.0 | 75.0 | 13.0 | 0.3 | 2.5 |

| SIL 70*80*9 | 70.0 | 80.0 | 9.0 | 0.3 | 2.5 |

| SIL 70*80*12.5 | 70.0 | 80.0 | 12.5 | 0.3 | 2.5 |

| SIL 70*85*11 | 70.0 | 85.0 | 11.0 | 0.4 | 4.0 |

| SIL 70*85*12.5 | 70.0 | 85.0 | 12.5 | 0.4 | 4.0 |

| SIL 70*90*13 | 70.0 | 90.0 | 13.0 | 0.6 | 5.0 |

| SIL 70*90*16 | 70.0 | 90.0 | 16.0 | 0.6 | 5.0 |

| SIL 75*85*12.5 | 75.0 | 85.0 | 12.5 | 0.3 | 2.5 |

| SIL 75*90*12.5 | 75.0 | 90.0 | 12.5 | 0.4 | 4.0 |

| SIL 80*90*11 | 80.0 | 90.0 | 11.0 | 0.3 | 2.5 |

| SIL 80*90*13 | 80.0 | 90.0 | 13.0 | 0.3 | 2.5 |

| SIL 80*95*11 | 80.0 | 95.0 | 11.0 | 0.4 | 4.0 |

| SIL 80*95*12.5 | 80.0 | 95.0 | 12.5 | 0.4 | 4.0 |

| SIL 80*100*13 | 80.0 | 100.0 | 13.0 | 0.6 | 5.0 |

| SIL 80*100*16 | 80.0 | 100.0 | 16.0 | 0.6 | 5.0 |

| SIL 85*100*12.5 | 85.0 | 100.0 | 12.5 | 0.4 | 4.0 |

| SIL 85*105*13 | 85.0 | 105.0 | 13.0 | 0.6 | 5.0 |

| SIL 90*105*12.5 | 90.0 | 105.0 | 12.5 | 0.4 | 4.0 |

| SIL 90*110*13 | 90.0 | 110.0 | 13.0 | 0.6 | 5.0 |

| SIL 90*110*16 | 90.0 | 110.0 | 16.0 | 0.6 | 5.0 |

| SIL 95*110*12.5 | 95.0 | 110.0 | 12.5 | 0.4 | 4.0 |

| SIL 95*115*13 | 95.0 | 115.0 | 13.0 | 0.6 | 5.0 |

| SIL 100*115*13 | 100.0 | 115.0 | 13.0 | 0.4 | 4.0 |

| SIL 100*120*13 | 100.0 | 120.0 | 13.0 | 0.6 | 5.0 |

| SIL 100*120*16 | 100.0 | 120.0 | 16.0 | 0.6 | 5.0 |

| SIL 105*115*11 | 105.0 | 115.0 | 11.0 | 0.3 | 2.5 |

| SIL 105*125*13 | 105.0 | 125.0 | 13.0 | 0.6 | 5.0 |

| SIL 110*130*16 | 110.0 | 130.0 | 16.0 | 0.6 | 5.0 |

| SIL 120*140*13 | 120.0 | 140.0 | 13.0 | 0.6 | 5.0 |

| SIL 120*140*16 | 120.0 | 140.0 | 16.0 | 0.6 | 5.0 |

| SIL 125*145*13 | 125.0 | 145.0 | 13.0 | 0.6 | 5.0 |

| SIL 125*145*16 | 125.0 | 145.0 | 16.0 | 0.6 | 5.0 |

| SIL 130*150*16 | 130.0 | 150.0 | 16.0 | 0.6 | 5.0 |

| SIL 140*160*16 | 140.0 | 160.0 | 16.0 | 0.6 | 5.0 |

| SIL 150*170*13 | 150.0 | 170.0 | 13.0 | 0.6 | 5.0 |

| SIL 150*170*16 | 150.0 | 170.0 | 16.0 | 0.6 | 5.0 |

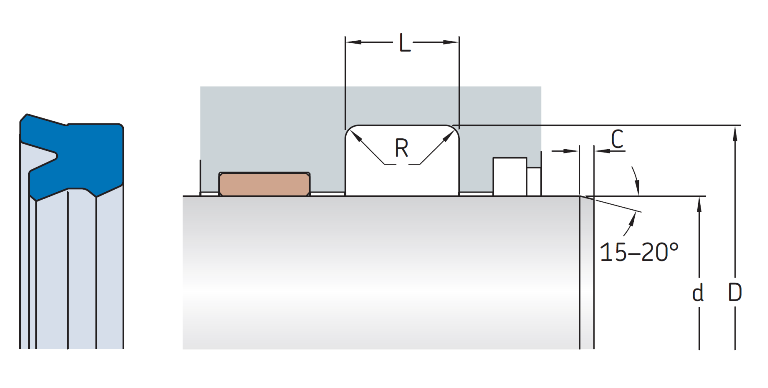

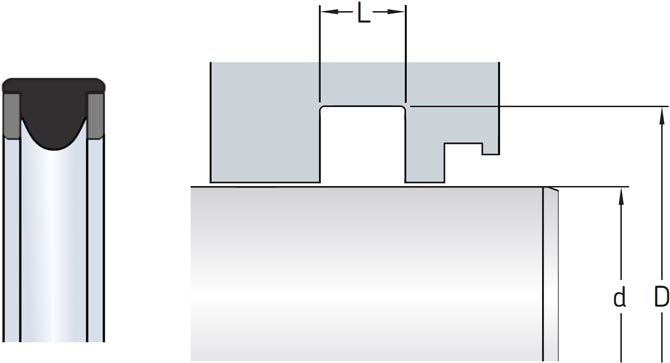

ZBR u-cups are made from self lubricating polyurethane and have a double lip design. ZBRs are suitable for heavy duty applications and are available in metric and imperial dimensions.

| Part No | (d) ±h9 | (D) ±H9 | (L) +0.2 | (R) max | (C) min |

|---|---|---|---|---|---|

| ZBR-14*22*5.7 | 14.0 | 22.0 | 5.7 | 0.2 | 6.0 |

| ZBR-16*24*5.7 | 16.0 | 24.0 | 5.7 | 0.2 | 6.0 |

| ZBR-18.26*5.7 | 18.0 | 26.0 | 5.7 | 0.2 | 6.0 |

| ZBR-20*28*5.7 | 20.0 | 28.0 | 5.7 | 0.2 | 6.0 |

| ZBR-22*30*5.7 | 22.0 | 30.0 | 5.7 | 0.2 | 6.0 |

| ZBR-22.4*30*5.7 | 22.4 | 30.0 | 5.7 | 0.2 | 6.0 |

| ZBR-25*33*5.7 | 25.0 | 33.0 | 5.7 | 0.2 | 6.0 |

| ZBR-25*33*8 | 25.0 | 33.0 | 8.0 | 0.2 | 6.0 |

| ZBR-28*35.5*5.7 | 28.0 | 35.0 | 5.7 | 0.2 | 6.0 |

| ZBR-28*36*6.4 | 28.0 | 36.0 | 6.4 | 0.2 | 6.0 |

| ZBR-30*38*7.8 | 30.0 | 38.0 | 7.8 | 0.2 | 6.0 |

| ZBR-30*40*7 | 30.0 | 40.0 | 7.0 | 0.2 | 6.0 |

| ZBR-32*40*6.4 | 32.0 | 40.0 | 6.4 | 0.2 | 6.0 |

| ZBR-32*42.0*8.3 | 32.0 | 42.0 | 8.3 | 0.2 | 6.0 |

| ZBR-35*43*7.8 | 35.0 | 43.0 | 7.8 | 0.2 | 6.0 |

| ZBR-35*45*7 | 35.0 | 45.0 | 7.0 | 0.2 | 6.0 |

| ZBR-35*45*11 | 35.0 | 45.0 | 11.0 | 0.2 | 6.0 |

| ZBR-40*50*7 | 40.0 | 50.0 | 7.0 | 0.2 | 6.0 |

| ZBR-40*50*11 | 40.0 | 50.0 | 11.0 | 0.2 | 6.0 |

| ZBR-40*55*11 | 40.0 | 55.0 | 11.0 | 0.5 | 8.5 |

| ZBR-40*55*12 | 40.0 | 55.0 | 12.0 | 0.5 | 8.5 |

| ZBR-45*60*11 | 45.0 | 60.0 | 11.0 | 0.5 | 8.5 |

| ZBR-45*55*7 | 45.0 | 55.0 | 7.0 | 0.2 | 6.0 |

| ZBR-45*55*8.3 | 45.0 | 55.0 | 8.3 | 0.2 | 6.0 |

| ZBR-45*55*11 | 45.0 | 55.0 | 11.0 | 0.2 | 6.0 |

| ZBR-45*60*12 | 45.0 | 60.0 | 12.0 | 0.5 | 8.5 |

| ZBR-45*60*12.5 | 45.0 | 60.0 | 12.5 | 0.2 | 8.5 |

| ZBR-50*65*11 | 50.0 | 65.0 | 11.0 | 0.5 | 8.5 |

| ZBR-50*65*12.4 | 50.0 | 65.0 | 12.4 | 0.5 | 8.5 |

| ZBR-50*60*7 | 50.0 | 60.0 | 7.0 | 0.2 | 6.0 |

| ZBR-50*60*8.3 | 50.0 | 62.0 | 8.3 | 0.2 | 6.0 |

| ZBR-50*60*8.5 | 50.0 | 63.0 | 8.5 | 0.2 | 6.0 |

| ZBR-53*63*7 | 53.0 | 63.0 | 7.0 | 0.2 | 6.0 |

| ZBR-55*65*7 | 55.0 | 65.0 | 7.0 | 0.2 | 6.0 |

| ZBR-55*65*9 | 55.0 | 65.0 | 9.0 | 0.2 | 6.0 |

| ZBR-55*65*11 | 55.0 | 65.0 | 11.0 | 0.2 | 6.0 |

| ZBR-55*68*11 | 55.0 | 68.0 | 11.0 | 0.2 | 7.5 |

| ZBR-55*70*10 | 55.0 | 70.0 | 10.0 | 0.5 | 8.5 |

| ZBR-55*70*11 | 55.0 | 70.0 | 11.0 | 0.5 | 8.5 |

| ZBR-55*70*12.4 | 55.0 | 70.0 | 12.4 | 0.2 | 8.5 |

| ZBR-55*75*13 | 55.0 | 75.0 | 13.0 | 0.8 | 6.0 |

| ZBR-56*71*12.4 | 56.0 | 71.0 | 12.4 | 0.5 | 8.5 |

| ZBR-60*68*9 | 60.0 | 68.0 | 9.0 | 0.2 | 6.0 |

| ZBR-60*70*7 | 60.0 | 70.0 | 7.0 | 0.2 | 6.0 |

| ZBR-60*70*11 | 60.0 | 70.0 | 11.0 | 0.2 | 6.0 |

| ZBR-60*73*11 | 60.0 | 73.0 | 11.0 | 0.2 | 7.5 |

| ZBR-60*75*10 | 60.0 | 75.0 | 10.0 | 0.5 | 8.5 |

| ZBR-60*80*13 | 60.0 | 80.0 | 13.0 | 0.8 | 11.0 |

| ZBR-63*73*7 | 63.0 | 73.0 | 7.0 | 0.2 | 6.0 |

| ZBR-63*78*12.4 | 63.0 | 78.0 | 12.4 | 0.5 | 8.5 |

| ZBR-63*78*13.5 | 63.0 | 78.0 | 13.5 | 0.5 | 6.0 |

| ZBR-65*75*7 | 65.0 | 75.0 | 7.0 | 0.2 | 6.0 |

| ZBR-65*78*11 | 65.0 | 78.0 | 11.0 | 0.2 | 7.5 |

| ZBR-65*80*10 | 65.0 | 80.0 | 10.0 | 0.5 | 8.5 |

| ZBR-65*80*10 | 65.0 | 80.0 | 10.0 | 0.5 | 8.5 |

| ZBR-65*80*13 | 65.0 | 85.0 | 13.0 | 0.8 | 11.0 |

| ZBR-65*85*13 | 65.0 | 85.0 | 13.0 | 0.8 | 11.0 |

| ZBR-70*80*7 | 70.0 | 80.0 | 7.0 | 0.2 | 6.0 |

| ZBR-70*83*11 | 70.0 | 83.0 | 11.0 | 0.2 | 7.5 |

| ZBR-70*85*10 | 70.0 | 85.0 | 10.0 | 0.5 | 8.5 |

| ZBR-70*85*11 | 70.0 | 85.0 | 11.0 | 0.5 | 8.5 |

| ZBR-70*85*12.4 | 70.0 | 85.0 | 12.4 | 0.5 | 8.5 |

| ZBR-70*90*13 | 70.0 | 90.0 | 13.0 | 0.8 | 11.0 |

| ZBR-75*85*7 | 75.0 | 85.0 | 7.0 | 0.2 | 6.0 |

| ZBR-75*88*11 | 75.0 | 88.0 | 11.0 | 0.2 | 7.5 |

| ZBR-75*90*10 | 75.0 | 90.0 | 10.0 | 0.5 | 8.5 |

| ZBR-75*90*11 | 75.0 | 90.0 | 11.0 | 0.5 | 8.5 |

| ZBR-75*95*13 | 75.0 | 95.0 | 13.0 | 0.8 | 11.0 |

| ZBR-80*90*7 | 80.0 | 90.0 | 7.0 | 0.2 | 6.0 |

| ZBR-80*93*11 | 80.0 | 93.0 | 11.0 | 0.2 | 7.5 |

| ZBR-80*95*10 | 80.0 | 95.0 | 10.0 | 0.5 | 8.5 |

| ZBR-80*95*12.4 | 80.0 | 95.0 | 12.4 | 0.5 | 8.5 |

| ZBR-80*100*13 | 80.0 | 100.0 | 13.0 | 0.8 | 11.0 |

| ZBR-85*100*10 | 85.0 | 100.0 | 10.0 | 0.5 | 8.5 |

| ZBR-85*100*11 | 85.0 | 100.0 | 11.0 | 0.5 | 8.5 |

| ZBR-85*100*13 | 85.0 | 100.0 | 13.0 | 0.5 | 8.5 |

| ZBR-85*105*13 | 85.0 | 105.0 | 13.0 | 0.8 | 11.0 |

| ZBR-90*105*11 | 90.0 | 105.0 | 11.0 | 0.5 | 8.5 |

| ZBR-90*105*12.4 | 90.0 | 105.0 | 12.4 | 0.5 | 8.5 |

| ZBR-90*110*13 | 90.0 | 110.0 | 13.0 | 0.8 | 11.0 |

| ZBR-95*110*10 | 95.0 | 110.0 | 10.0 | 0.5 | 8.5 |

| ZBR-95*110*11 | 95.0 | 110.0 | 11.0 | 0.5 | 8.5 |

| ZBR-95*115*13 | 95.0 | 115.0 | 13.0 | 0.8 | 11.0 |

| ZBR-100*112*15 | 100.0 | 112.0 | 15.0 | 0.2 | 7.0 |

| ZBR-100*115*10 | 100.0 | 115.0 | 10.0 | 0.5 | 8.5 |

| ZBR-100*115*11 | 100.0 | 115.0 | 11.0 | 0.5 | 8.5 |

| ZBR-100*115*12.5 | 100.0 | 115.0 | 12.0 | 0.5 | 8.5 |

| ZBR-100*120*13 | 100.0 | 120.0 | 13.0 | 0.8 | 11.0 |

| ZBR-100*120*15.5 | 100.0 | 12.0 | 15.5 | 0.8 | 11.0 |

| ZBR-105*120*10 | 105.0 | 120.0 | 10.0 | 0.5 | 8.5 |

| ZBR-105*125*16.5 | 105.0 | 125.0 | 16.5 | 0.8 | 11.0 |

| ZBR-110*125*11 | 110.0 | 125.0 | 11.0 | 0.5 | 8.5 |

| ZBR-110*130*16.5 | 110.0 | 130.0 | 16.5 | 0.8 | 11.0 |

| ZBR-112*125*10 | 112.0 | 125.0 | 10.0 | 0.2 | 7.5 |

| ZBR-118*133*10 | 118.0 | 133.0 | 10.0 | 0.5 | 8.5 |

| ZBR-120*140*10 | 120.0 | 140.0 | 10.0 | 0.5 | 8.5 |

| ZBR-125*140*16.5 | 125.0 | 140.0 | 16.5 | 0.8 | 11.0 |

| ZBR-125*145*16.5 | 125.0 | 145.0 | 16.5 | 0.8 | 11.0 |

| ZBR-130*145*12 | 130.0 | 145.0 | 12.0 | 0.5 | 8.5 |

| ZBR-130*150*16.5 | 130.0 | 150.0 | 16.5 | 0.2 | 11.0 |

| ZBR-136*150*10 | 136.0 | 150.0 | 10.0 | 0.5 | 8.5 |

| ZBR-140*155*10 | 140.0 | 155.0 | 10.0 | 0.5 | 8.5 |

| ZBR-140*160*16.5 | 140.0 | 160.0 | 16.5 | 0.8 | 11.0 |

| ZBR-145*160*10 | 145.0 | 160.0 | 10.0 | 0.5 | 8.5 |

| ZBR-150*170*16.5 | 150.0 | 170.0 | 16.5 | 0.8 | 11.0 |

| ZBR-160*180*16.5 | 160.0 | 180.0 | 16.5 | 0.8 | 11.0 |

| ZBR-160*185*19.7 | 160.0 | 185.0 | 19.7 | 0.8 | 13.0 |

| ZBR-180*200*13.5 | 180.0 | 200.0 | 13.5 | 0.8 | 11.0 |

| ZBR-200*220*13.5 | 200.0 | 220.0 | 13.5 | 0.8 | 11.0 |

| ZBR-230*250*13.5 | 230.0 | 250.0 | 13.5 | 0.8 | 11.0 |

| ZBR-240*260*16.5 | 240.0 | 260.0 | 16.5 | 0.8 | 11.0 |

| ZBR-255*280*20.5 | 255.0 | 280.0 | 20.5 | 0.8 | 13.0 |

| Part No | (d) | ± | (D) | ± | (L) +.010 | (R) max | (C) min |

|---|---|---|---|---|---|---|---|

| ZBR125-750-250 | 0.750 | -.001 | 1.000 | +.002 | 0.275 | 0.015 | 0.250 |

| ZBR125-1000-250 | 1.000 | -.001 | 1.250 | +.002 | 0.275 | 0.015 | 0.250 |

| ZBR125-1125-187 | 1.125 | -.001 | 1.375 | +.002 | 0.213 | 0.015 | 0.250 |

| ZBR125-1125-250 | 1.125 | -.001 | 1.375 | +.002 | 0.275 | 0.015 | 0.250 |

| ZBR187-1125-312 | 1.125 | -.002 | 1.500 | +.002 | 0.343 | 0.015 | 0.250 |

| ZBR125-1250-187 | 1.250 | -.001 | 1.500 | +.002 | 0.213 | 0.015 | 0.250 |

| ZBR125-1250-197 | 1.250 | -.001 | 1.500 | +.002 | 0.223 | 0.015 | 0.250 |

| ZBR125-1250-250 | 1.250 | -.001 | 1.500 | +.002 | 0.275 | 0.015 | 0.250 |

| ZBR187-1250-250 | 1.250 | -.002 | 1.625 | +.002 | 0.275 | 0.015 | 0.250 |

| ZBR187-1250-312 | 1.250 | -.002 | 1.625 | +.002 | 0.343 | 0.015 | 0.250 |

| ZBR125-1375-250 | 1.375 | -.001 | 1.625 | +.002 | 0.275 | 0.015 | 0.250 |

| ZBR125-1500-250 | 1.500 | -.001 | 1.750 | +.002 | 0.275 | 0.015 | 0.250 |

| ZBR187-1500-312 | 1.500 | -.002 | 1.875 | +.002 | 0.343 | 0.015 | 0.250 |

| ZBR187-1500-375 | 1.500 | -.002 | 1.875 | +.002 | 0.413 | 0.015 | 0.250 |

| ZBR250-1500-375 | 1.500 | -.002 | 2.000 | +.003 | 0.413 | 0.020 | 0.312 |

| ZBR187-1750-312 | 1.750 | -.002 | 2.125 | +.002 | 0.343 | 0.015 | 0.250 |

| ZBR187-1750-375 | 1.750 | -.002 | 2.125 | +.002 | 0.413 | 0.015 | 0.250 |

| ZBR250-1750-375 | 1.750 | -.002 | 2.250 | +.003 | 0.413 | 0.020 | 0.312 |

| ZBR250-1875-375 | 1.875 | -.002 | 2.375 | +.003 | 0.413 | 0.020 | 0.312 |

| ZBR187-2000-312 | 2.000 | -.002 | 2.375 | +.002 | 0.343 | 0.015 | 0.250 |

| ZBR187-2000-375 | 2.000 | -.002 | 2.375 | +.002 | 0.413 | 0.015 | 0.250 |

| ZBR250-2000-375 | 2.000 | -.002 | 2.500 | +.003 | 0.413 | 0.020 | 0.312 |

| ZBR187-2250-335 | 2.250 | -.002 | 2.625 | +.002 | 0.369 | 0.015 | 0.250 |

| ZBR250-2250-375 | 2.250 | -.003 | 2.750 | +.003 | 0.413 | 0.020 | 0.312 |

| ZBR250-2500-375 | 2.500 | -.002 | 3.000 | +.003 | 0.413 | 0.020 | 0.312 |

| ZBR250-2625-375 | 2.625 | -.002 | 3.125 | +.003 | 0.413 | 0.020 | 0.312 |

| ZBR250-2875-375 | 2.875 | -.002 | 3.375 | +.003 | 0.413 | 0.020 | 0.312 |

| ZBR250-3000-375 | 3.000 | -.002 | 3.500 | +.003 | 0.413 | 0.020 | 0.312 |

| ZBR250-3250-375 | 3.250 | -.002 | 3.750 | +.003 | 0.413 | 0.020 | 0.312 |

| ZBR250-3500-375 | 3.500 | -.002 | 4.000 | +.003 | 0.413 | 0.020 | 0.312 |

| ZBR312-3750-500 | 3.750 | -.002 | 4.375 | +.004 | 0.550 | 0.020 | 0.375 |

| ZBR250-4000-375 | 4.000 | -.002 | 4.500 | +.003 | 0.413 | 0.020 | 0.312 |

| ZBR250-4750-625 | 4.750 | -.002 | 5.250 | +.003 | 0.688 | 0.020 | 0.312 |

| ZBR250-5000-375 | 5.000 | -.002 | 5.500 | +.003 | 0.413 | 0.020 | 0.312 |

| ZBR250-5000-562 | 5.000 | -.002 | 5.500 | +.003 | 0.618 | 0.020 | 0.312 |

| ZBR250-5250-562 | 5.250 | -.002 | 5.750 | +.003 | 0.618 | 0.020 | 0.312 |

| ZBR250-5500-562 | 5.500 | -.002 | 6.000 | +.003 | 0.618 | 0.020 | 0.312 |

| ZBR375-5500-625 | 5.500 | -.002 | 6.250 | +.005 | 0.688 | 0.035 | 0.500 |

| ZBR375-6500-625 | 6.500 | -.002 | 7.250 | +.005 | 0.688 | 0.035 | 0.500 |

| ZBR500-6500-750 | 6.500 | -.003 | 7.500 | +.007 | 0.825 | 0.035 | 0.625 |

| ZBR500-7000-750 | 7.000 | -.003 | 8.000 | +.007 | 0.825 | 0.035 | 0.625 |

| ZBR375-7750-625 | 7.750 | -.002 | 8.500 | +.005 | 0.688 | 0.035 | 0.500 |

| ZBR375-8000-625 | 8.000 | -.002 | 8.750 | +.005 | 0.688 | 0.035 | 0.500 |

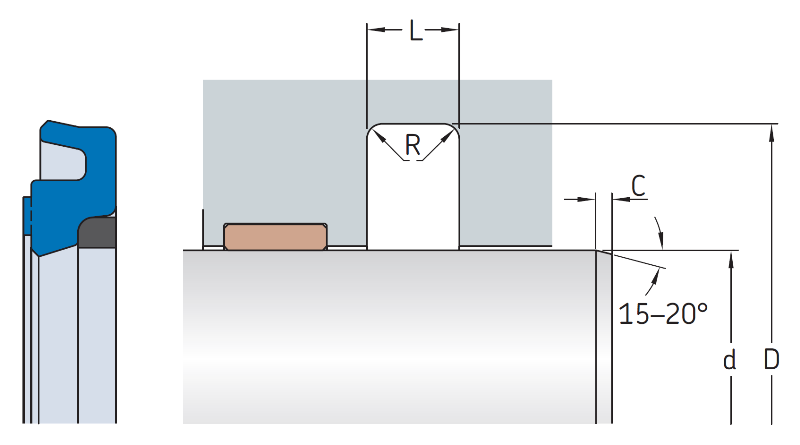

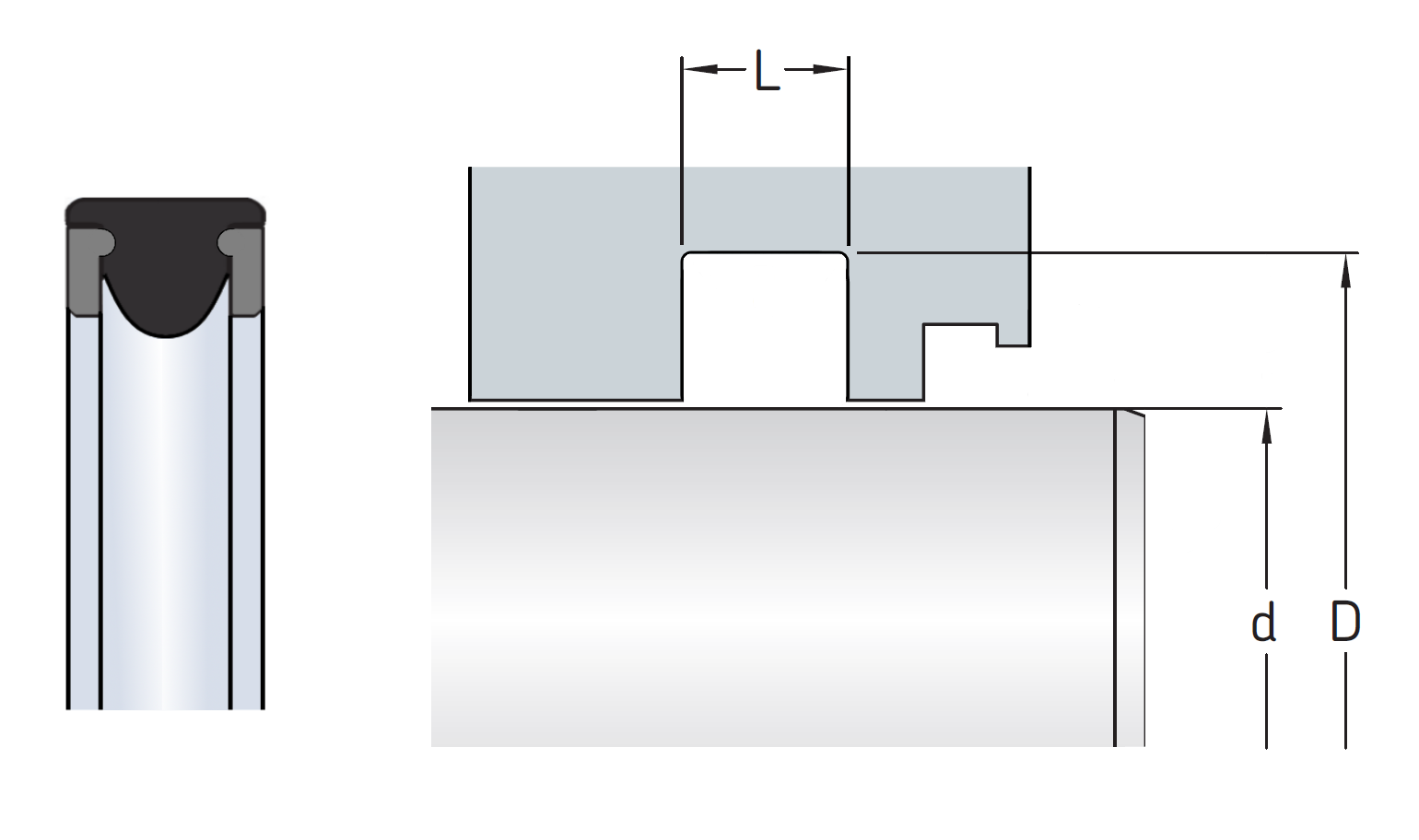

RBB profiles have a self lubricating seal ring that incorporates a polyimide (PA) or polyacetal (POM) anti-extrusion ring. The flexible outside static sealing lip and channels in the front face ensure that pressure can return to the system side of the buffer and prevent build up of pressure between the rod and buffer seals. These profiles are suitable for pressure peaks and demanding workloads in heavy duty applications up to 690 bar (10,000 psi).

| Part No | (d) ±h9 | (D) ±H9 | (L) +0.2 | (R) max | (C) min |

|---|---|---|---|---|---|

| RBB-40*55.5*6.3 | 40.0 | 55.5 | 6.3 | 0.55 | 6.0 |

| RBB-45*60.5*6.3 | 45.0 | 60.5 | 6.3 | 0.55 | 6.0 |

| RBB-50*65.5*6.3 | 50.0 | 65.5 | 6.3 | 0.55 | 6.0 |

| RBB-55*70.5*6.3 | 55.0 | 70.5 | 6.3 | 0.7 | 8.0 |

| RBB-60*75.5*6.3 | 60.0 | 75.5 | 6.3 | 0.7 | 8.0 |

| RBB-65*80.5*6.3 | 65.0 | 80.5 | 6.3 | 0.7 | 8.0 |

| RBB-70*85.5*6.3 | 70.0 | 85.5 | 6.3 | 0.7 | 8.0 |

| RBB-75*90.5*6.3 | 75.0 | 90.5 | 6.3 | 0.7 | 8.0 |

| RBB-80*95.5*6.3 | 80.0 | 95.5 | 6.3 | 0.7 | 8.0 |

| RBB-85*100.5*6.3 | 85.0 | 100.5 | 6.3 | 0.7 | 8.0 |

| RBB-90*105.5*6.3 | 90.0 | 105.5 | 6.3 | 0.7 | 8.0 |

| RBB-95*110.5*6.3 | 95.0 | 110.5 | 6.3 | 0.7 | 8.0 |

| RBB-100*115.5*6.3 | 100.0 | 115.5 | 6.3 | 0.7 | 8.0 |

| RBB-105*120.5*6.3 | 105.0 | 120.5 | 6.3 | 0.7 | 8.0 |

| RBB-110*125.5*6.3 | 110.0 | 125.5 | 6.3 | 0.7 | 8.0 |

| RBB-115*130.5*6.3 | 115.0 | 130.5 | 6.3 | 0.7 | 8.0 |

| RBB-120*135.5*6.3 | 120.0 | 135.5 | 6.3 | 0.7 | 8.0 |

| RBB-125*140.5*6.3 | 125.0 | 140.5 | 6.3 | 0.7 | 8.0 |

| RBB-130*145.5*6.3 | 130.0 | 145.5 | 6.3 | 0.7 | 8.0 |

| RBB-140*155.5*6.3 | 140.0 | 155.5 | 6.3 | 0.7 | 8.0 |

| RBB-150*165.5*6.3 | 150.0 | 165.5 | 6.3 | 0.7 | 8.0 |

| RBB-160*175.5*6.3 | 160.0 | 175.5 | 6.3 | 0.7 | 8.0 |

| RBB-170*185.5*6.3 | 170.0 | 185.5 | 6.3 | 0.7 | 8.0 |

| RBB-180*195.5*6.3 | 180.0 | 195.5 | 6.3 | 0.7 | 8.0 |

| Part No | (d) | ± | (D) | ± | (L) +.010 | (R) max | (C) min |

|---|---|---|---|---|---|---|---|

| RBB3-2000 | 2.000 | -.004 | 2.494 | +.005 | 0.247 | 0.028 | 0.312 |

| RBB2-2250 | 2.250 | -.003 | 2.582 | +.004 | 0.166 | 0.022 | 0.250 |

| RBB2-2500 | 2.500 | -.003 | 2.832 | +.004 | 0.166 | 0.022 | 0.250 |

| RBB3-2500 | 2.500 | -.004 | 2.994 | +.005 | 0.247 | 0.028 | 0.312 |

| RBB3-2750 | 2.750 | -.004 | 3.244 | +.005 | 0.247 | 0.028 | 0.312 |

| RBB3-3000 | 3.000 | -.004 | 3.494 | +.005 | 0.247 | 0.028 | 0.312 |

| RBB3-3500 | 3.500 | -.004 | 3.994 | +.005 | 0.247 | 0.028 | 0.312 |

| RBB3-4000 | 4.000 | -.004 | 4.494 | +.005 | 0.247 | 0.028 | 0.312 |

| RBB3-4500 | 4.500 | -.004 | 4.994 | +.005 | 0.247 | 0.028 | 0.312 |

| RBB3-4750 | 4.750 | -.004 | 5.244 | +.005 | 0.247 | 0.028 | 0.312 |

| RBB3-5000 | 5.000 | -.004 | 5.494 | +.005 | 0.247 | 0.028 | 0.312 |

| RBB3-5500 | 5.500 | -.004 | 5.994 | +.005 | 0.247 | 0.028 | 0.312 |

| RBB3-6000 | 6.000 | -.004 | 6.494 | +.005 | 0.247 | 0.028 | 0.312 |

| RBB3-6500 | 6.500 | -.004 | 6.994 | +.005 | 0.247 | 0.028 | 0.312 |

| RBB3-7000 | 7.000 | -.004 | 7.494 | +.005 | 0.247 | 0.028 | 0.312 |

| RBB3-7250 | 7.250 | -.004 | 7.744 | +.005 | 0.247 | 0.028 | 0.312 |

| RBB3-8000 | 8.000 | -.004 | 8.494 | +.005 | 0.247 | 0.028 | 0.312 |

S9B profiles have a nitrile rubber o’ring energiser and a bronze filled PTFE slide ring as standard. Depending on the application, the slide rings can be manufactured from a variety of PTFE and polyurethane materials for improved chemical resistance, wear resistance and ease of installation. S9B profiles with a PTFE slide ring are suitable for pressures up to 400 bar (5,800 psi).

| Part No | (d) ±f8 | (D) ± H9 | (L) +0.2 | (R) max | (C) min |

|---|---|---|---|---|---|

| S9B-8*12.9*2.2 | 8.0 | 12.9 | 2.2 | 0.6 | 3.5 |

| S9B-8*15.3*3.2 | 8.0 | 15.3 | 3.2 | 0.6 | 3.5 |

| S9B-10*14.9*2.2 | 10.0 | 14.9 | 2.2 | 0.6 | 3.5 |

| S9B-10*17.3*3.2 | 10.0 | 17.3 | 3.2 | 0.6 | 3.5 |

| S9B-12*16.9*2.2 | 12.0 | 16.9 | 2.2 | 0.6 | 3.5 |

| S9B-12*19.3*3.2 | 12.0 | 19.3 | 3.2 | 0.6 | 3.5 |

| S9B-14*18.9*2.2 | 14.0 | 18.9 | 2.2 | 0.6 | 3.5 |

| S9B-14*21.3*3.2 | 14.0 | 21.3 | 3.2 | 0.6 | 3.5 |

| S9B-15*22.3*3.2 | 15.0 | 22.3 | 3.2 | 0.6 | 3.5 |

| S9B-16*23.3*3.2 | 16.0 | 23.3 | 3.2 | 0.6 | 3.5 |

| S9B-18*25.3*3.2 | 18.0 | 25.3 | 3.2 | 0.6 | 3.5 |

| S9B-20*27.3*3.2 | 20.0 | 27.3 | 3.2 | 0.6 | 3.5 |

| S9B-20*30.7*4.2 | 20.0 | 30.7 | 4.2 | 1.0 | 4.5 |

| S9B-22*29.3*3.2 | 22.0 | 29.3 | 3.2 | 1.0 | 4.5 |

| S9B-22*32.7*4.2 | 22.0 | 32.7 | 4.2 | 1.0 | 4.5 |

| S9B-25*32.3*3.2 | 25.0 | 32.3 | 3.2 | 1.0 | 4.5 |

| S9B-25*35.7*4.2 | 25.0 | 35.7 | 4.2 | 1.0 | 4.5 |

| S9B-28*35.3*3.2 | 28.0 | 35.3 | 3.2 | 1.0 | 4.5 |

| S9B-28*38.7*4.2 | 28.0 | 38.7 | 4.2 | 1.0 | 4.5 |

| S9B-30*37.3*32 | 30.0 | 37.3 | 3.2 | 1.0 | 4.5 |

| S9B-30*40.4*4.2 | 30.0 | 40.7 | 4.2 | 1.0 | 4.5 |

| S9B-32*39.3*3.2 | 32.0 | 39.3 | 3.2 | 1.0 | 4.5 |

| S9B-32*42.7*4.2 | 32.0 | 42.7 | 4.2 | 1.0 | 4.5 |

| S9B-35*42.3*3.2 | 35.0 | 42.3 | 3.2 | 1.0 | 4.5 |

| S9B-35*45.7*4.2 | 35.0 | 45.7 | 4.2 | 1.0 | 4.5 |

| S9B-36*46.7*4.2 | 36.0 | 46.7 | 4.2 | 1.0 | 4.5 |

| S9B-40*50.7*4.2 | 40.0 | 50.7 | 4.2 | 1.3 | 5.0 |

| S9B-40*55.1*6.3 | 40.0 | 55.1 | 6.3 | 1.3 | 5.0 |

| S9B-45*55.7*4.2 | 45.0 | 55.7 | 4.2 | 1.3 | 5.0 |

| S9B-45*60.1*6.3 | 45.0 | 60.1 | 6.3 | 1.3 | 5.0 |

| S9B-50*61*4.2 | 50.0 | 61 | 4.2 | 1.3 | 5.0 |

| S9B-50*65.1*6.3 | 50.0 | 65.1 | 6.3 | 1.3 | 5.0 |

| S9B-55*70.1*6.3 | 55.0 | 70.1 | 6.3 | 1.3 | 5.0 |

| S9B-56*66.7*4.2 | 56.0 | 66.7 | 4.2 | 1.3 | 5.0 |

| S9B-56*71.1*6.3 | 56.0 | 71.1 | 6.3 | 1.3 | 5.0 |

| S9B-60*70.7*4.2 | 60.0 | 70.7 | 4.2 | 1.3 | 5.0 |

| S9B-60*75.1*6.3 | 60.0 | 75.1 | 6.3 | 1.3 | 5.0 |

| S9B-63*78.1*6.3 | 63.0 | 78.1 | 6.3 | 1.3 | 5.0 |

| S9B-65*80.1*6.3 | 65.0 | 80.1 | 6.3 | 1.3 | 5.0 |

| S9B-70*85.1*6.3 | 70.0 | 85.1 | 6.3 | 1.3 | 5.0 |

| S9B-75*90.1*6.3 | 75.0 | 90.1 | 6.3 | 1.3 | 5.0 |

| S9B-80*95.1*6.3 | 80.0 | 95.1 | 6.3 | 1.3 | 5.0 |

| S9B-85*100.1*6.3 | 85.0 | 100.1 | 6.3 | 1.3 | 5.0 |

| S9B-90*105.1*6.3 | 90.0 | 105.1 | 6.3 | 1.3 | 5.0 |

| S9B-95*110.1*6.3 | 95.0 | 110.1 | 6.3 | 1.3 | 5.0 |

| S9B-100*115.1*6.3 | 100.0 | 115.1 | 6.3 | 1.3 | 5.0 |

| S9B-105*120.1*6.3 | 105.0 | 120.1 | 6.3 | 1.3 | 5.0 |

| S9B-110*125.1*6.3 | 110.0 | 125.1 | 6.3 | 1.3 | 5.0 |

| S9B-115*130.1*6.3 | 115.0 | 130.1 | 6.3 | 1.3 | 5.0 |

| S9B-120*135.1*6.3 | 120.0 | 135.1 | 6.3 | 1.3 | 5.0 |

| S9B-125*140.1*6.3 | 125.0 | 140.1 | 6.3 | 1.3 | 5.0 |

| S9B-130*145.1*6.3 | 130.0 | 145.1 | 6.3 | 1.3 | 5.0 |

| S9B-135*150.1*6.3 | 135.0 | 150.1 | 6.3 | 1.3 | 5.0 |

| S9B-140*155.1*6.3 | 140.0 | 155.1 | 6.3 | 1.3 | 5.0 |

| S9B-150*165.1*6.3 | 150.0 | 165.1 | 6.3 | 1.3 | 5.0 |

| S9B-160*175.1*6.3 | 160.0 | 175.1 | 6.3 | 1.3 | 5.0 |

| S9B-180*195.1*6.3 | 180.0 | 195.1 | 6.3 | 1.3 | 5.0 |

| S9B-240*260.5*8.1 | 240.0 | 260.5 | 8.1 | 1.8 | 6.0 |

| Part No | (d) | ± | (D) | ± | (L) +.010 | (C) min |

|---|---|---|---|---|---|---|

| S9B1-1000 | 1.000 | -.002 | 1.298 | +.003 | 0.126 | 0.140 |

| S9B2-1000 | 1.000 | -.003 | 1.424 | +.004 | 0.166 | 0.180 |

| S9B1-1125 | 1.125 | -.002 | 1.423 | +.003 | 0.126 | 0.140 |

| S9B1-1250 | 1.250 | -.002 | 1.548 | +.003 | 0.126 | 0.140 |

| S9B2-1250 | 1.250 | -.003 | 1.674 | +.004 | 0.166 | 0.180 |

| S9B2-1375 | 1.375 | -.003 | 1.799 | +.004 | 0.165 | 0.180 |

| S9B1-1500 | 1.500 | -.002 | 1.798 | +.003 | 0.126 | 0.140 |

| S9B2-1500 | 1.500 | -.003 | 1.924 | +.004 | 0.166 | 0.180 |

| S9B3-1500 | 1.500 | -.004 | 2.116 | +.005 | 0.247 | 0.200 |

| S9B1-1750 | 1.750 | -.002 | 2.048 | +.003 | 0.126 | 0.140 |

| S9B2-1750 | 1.750 | -.003 | 2.174 | +.004 | 0.166 | 0.180 |

| S9B3-1750 | 1.750 | -.004 | 2.366 | +.005 | 0.247 | 0.200 |

| S9B2-1875 | 1.875 | -.003 | 2.299 | +.004 | 0.166 | 0.180 |

| S9B2-2000 | 2.000 | -.003 | 2.424 | +.004 | 0.166 | 0.180 |

| S9B3-2000 | 2.000 | -.004 | 2.616 | +.005 | 0.247 | 0.200 |

| S9B2-2250 | 2.250 | -.003 | 2.674 | +.004 | 0.166 | 0.180 |

| S9B3-2250 | 2.250 | -.004 | 2.866 | +.005 | 0.247 | 0.200 |

| S9B2-2500 | 2.500 | -.003 | 2.924 | +.004 | 0.166 | 0.180 |

| S9B3-2500 | 2.500 | -.004 | 3.116 | +.005 | 0.247 | 0.200 |

| S9B3-2625 | 2.625 | -.004 | 3.241 | +.005 | 0.247 | 0.200 |

| S9B2-3000 | 3.000 | -.003 | 3.424 | +.004 | 0.166 | 0.180 |

| S9B3-3000 | 3.000 | -.004 | 3.616 | +.005 | 0.247 | 0.200 |

| S9B3-3250 | 3.250 | -.004 | 3.866 | +.005 | 0.247 | 0.200 |

| S9B3-3500 | 3.500 | -.004 | 4.116 | +.005 | 0.247 | 0.200 |

| S9B3-3750 | 3.750 | -.004 | 4.366 | +.005 | 0.247 | 0.200 |

| S9B2-4000 | 4.000 | -.003 | 4.424 | +.004 | 0.166 | 0.180 |

| S9B3-4000 | 4.000 | -.004 | 4.616 | +.005 | 0.247 | 0.200 |

| S9B4-4000 | 4.000 | -.005 | 4.830 | +.006 | 0.320 | 0.250 |

| S9B3-4250 | 4.250 | -.004 | 4.866 | +.005 | 0.247 | 0.200 |

| S9B3-4500 | 4.500 | -.004 | 5.116 | +.005 | 0.247 | 0.200 |

| S9B4-4500 | 4.500 | -.005 | 5.330 | +.006 | 0.320 | 0.250 |

| S9B3-4750 | 4.750 | -.004 | 5.366 | +.005 | 0.247 | 0.200 |

| S9B4-4750 | 4.750 | -.005 | 5.580 | +.006 | 0.320 | 0.250 |

| S9B3-5000 | 5.000 | -.004 | 5.616 | +.005 | 0.247 | 0.200 |

| S9B4-5000 | 5.000 | -.005 | 5.830 | +.006 | 0.320 | 0.250 |

| S9B3-5250 | 5.250 | -.004 | 5.866 | +.005 | 0.247 | 0.200 |

| S9B4-5250 | 5.250 | -.005 | 6.080 | +.006 | 0.320 | 0.250 |

| S9B3-5500 | 5.500 | -.004 | 6.116 | +.005 | 0.247 | 0.200 |

| S9B4-5500 | 5.500 | -.005 | 6.330 | +.006 | 0.320 | 0.250 |

| S9B3-5750 | 5.750 | -.004 | 6.366 | +.005 | 0.247 | 0.200 |

| S9B4-5750 | 5.750 | -.005 | 6.580 | +.006 | 0.320 | 0.250 |

| S9B3-6000 | 6.000 | -.004 | 6.616 | +.005 | 0.247 | 0.200 |

| S9B4-6000 | 6.000 | -.005 | 6.830 | +.006 | 0.320 | 0.250 |

| S9B3-6250 | 6.250 | -.004 | 6.866 | +.005 | 0.247 | 0.200 |

| S9B4-6250 | 6.250 | -.005 | 7.080 | +.006 | 0.320 | 0.250 |

| S9B3-6500 | 6.500 | -.004 | 7.116 | +.005 | 0.247 | 0.200 |

| S9B4-6500 | 6.500 | -.005 | 7.330 | +.006 | 0.320 | 0.250 |

| S9B3-6750 | 6.750 | -.004 | 7.366 | +.005 | 0.247 | 0.200 |

| S9B4-6750 | 6.750 | -.005 | 7.580 | +.006 | 0.320 | 0.250 |

| S9B3-7000 | 7.000 | -.004 | 7.616 | +.005 | 0.247 | 0.200 |

| S9B4-7000 | 7.000 | -.005 | 7.830 | +.006 | 0.320 | 0.250 |

| S9B3-7250 | 7.250 | -.004 | 7.866 | +.005 | 0.247 | 0.200 |

| S9B4-7250 | 7.250 | -.005 | 8.080 | +.006 | 0.320 | 0.250 |

| S9B3-7500 | 7.500 | -.004 | 8.116 | +.005 | 0.247 | 0.200 |

| S9B4-7500 | 7.500 | -.005 | 8.330 | +.006 | 0.320 | 0.250 |

| S9B3-7750 | 7.750 | -.004 | 8.366 | +.005 | 0.247 | 0.200 |

| S9B4-7750 | 7.750 | -.005 | 8.580 | +.006 | 0.320 | 0.250 |

| S9B4-8000 | 8.000 | -.005 | 8.830 | +.006 | 0.320 | 0.250 |

| S9B4-8500 | 8.500 | -.005 | 9.330 | +.006 | 0.320 | 0.250 |

| S9B4-9000 | 9.000 | -.005 | 9.830 | +.006 | 0.320 | 0.250 |

| S9B4-9500 | 9.500 | -.005 | 10.330 | +.006 | 0.320 | 0.250 |

| S9B4-10000 | 10.000 | -.005 | 10.830 | +.006 | 0.320 | 0.250 |

Designed to fit imperial o’ring housings in accordance to ISO3601 (BS1806/AS568A o’ring sizing), T-seals are an ideal replacement for o’rings. The T-shaped sealing element serves as a slide ring that’s highly resistant twisting and spiral failure. Rod T-seals seal statically against the groove OD and are suitable for pressures up to 345 bar (5,000 psi).

MRT profiles have a nitrile (NBR) rubber sealing element supported by hard polyamide non-locking anti-extrusion rings.

| Part No | Nom | (d) | (D) | (L) | O’ring Ref |

|---|---|---|---|---|---|

| MRT-001 | 3/16*3/8*3/32 | 0.186 | 0.362 | 0.140 | BS106 |

| MRT-002 | 1/4*7/16*3/32 | 0.249 | 0.425 | 0.140 | BS108 |

| MRT-003 | 5/16*1/2*3/32 | 0.311 | 0.487 | 0.140 | BS109 |

| MRT-004 | 3/8*5/8*1/8 | 0.373 | 0.615 | 0.187 | BS204 |

| MRT-006 | 1/2*3/4*1/8 | 0.498 | 0.740 | 0.187 | BS206 |

| MRT-007 | 9/16*13/16*1/8 | 0.560 | 0.802 | 0.187 | BS207 |

| MRT-008 | 5/8*7/8*1/8 | 0.623 | 0.865 | 0.187 | BS208 |

| MRT-009 | 11/16*15/16*1/8 | 0.685 | 0.927 | 0.187 | BS209 |

| MRT-010 | 3/4*1*1/8 | 0.748 | 0.990 | 0.187 | BS210 |

| MRT-011 | 13/16*1-1/16*1/8 | 0.810 | 1.052 | 0.187 | BS211 |

| MRT-012 | 7/8*1-1/8*1/8 | 0.873 | 1.115 | 0.187 | BS212 |

| MRT-013 | 15/16*1-3/16*1/8 | 0.935 | 1.177 | 0.187 | BS213 |

| MRT-014 | 1*1-1/4*1/8 | 0.998 | 1.240 | 0.187 | BS214 |

| MRT-015 | 1-1/16*1-5/16*1/8 | 1.060 | 1.302 | 0.187 | BS215 |

| MRT-016 | 1-1/8*1-3/8*1/8 | 1.123 | 1.365 | 0.187 | BS216 |

| MRT-017 | 1-3/16*1-7/16*1/8 | 1.185 | 1.427 | 0.187 | BS217 |

| MRT-018 | 1-1/4*1-1/2*1/8 | 1.248 | 1.490 | 0.187 | BS218 |

| MRT-019 | 1-5/16*1-9/16*1/8 | 1.310 | 1.552 | 0.187 | BS219 |

| MRT-020 | 1-3/8*1-5/8*1/8 | 1.373 | 1.615 | 0.187 | BS220 |

| MRT-021 | 1-7/16*1-11/16*1/8 | 1.435 | 1.677 | 0.187 | BS221 |

| MRT-022 | 1-1/2*1-3/4*1/8 | 1.498 | 1.740 | 0.187 | BS222 |

| MRT-023 | 1-1/2*1-7/8*3/16 | 1.498 | 1.868 | 0.281 | BS325 |

| MRT-024 | 1-5/8*2*3/16 | 1.625 | 1.993 | 0.281 | BS326 |

| MRT-025 | 1-3/4*2-1/8*3/16 | 1.748 | 2.118 | 0.281 | BS327 |

| MRT-026 | 1-7/8*2-1/4*3/16 | 1.873 | 2.243 | 0.281 | BS328 |

| MRT-027 | 2*2-3/8*3/16 | 1.998 | 2.368 | 0.281 | BS329 |

| MRT-028 | 2-1/8*2-1/2*3/16 | 2.123 | 2.493 | 0.281 | BS330 |

| MRT-029 | 2-1/4*2-5/8*3/16 | 2.248 | 2.618 | 0.281 | BS331 |

| MRT-030 | 2-3/8*2-3/4*3/16 | 2.373 | 2.743 | 0.281 | BS332 |

| MRT-031 | 2-1/2*2-7/8*3/16 | 2.498 | 2.868 | 0.281 | BS333 |

| MRT-032 | 2-5/8*3*3/16 | 2.623 | 2.993 | 0.281 | BS334 |

| MRT-033 | 2-3/4*3-1/8*3/16 | 2.748 | 3.118 | 0.281 | BS335 |

| MRT-034 | 2-7/8*3-1/4*3/16 | 2.873 | 3.243 | 0.281 | BS336 |

| MRT-035 | 3*3-3/8*3/16 | 2.998 | 3.368 | 0.281 | BS337 |

| MRT-036 | 3-1/8*3-1/2*3/16 | 3.123 | 3.493 | 0.281 | BS338 |

| MRT-037 | 3-1/4*3-5/8*3/16 | 3.248 | 3.618 | 0.281 | BS339 |

| MRT-038 | 3-3/8*3-3/4*3/16 | 3.373 | 3.743 | 0.281 | BS340 |

| MRT-039 | 3-1/2*3-7/8*3/16 | 3.498 | 3.868 | 0.281 | BS341 |

| MRT-040 | 3-5/8*4*3/16 | 3.623 | 3.993 | 0.281 | BS342 |

| MRT-041 | 3-3/4*4-1/8*3/16 | 3.748 | 4.118 | 0.281 | BS343 |

| MRT-042 | 3-7/8*4-1/4*3/16 | 3.873 | 4.243 | 0.281 | BS344 |

| MRT-043 | 4*4-3/8*3/16 | 3.998 | 4.368 | 0.281 | BS345 |

| MRT-044 | 4-1/8*4-1/2*3/16 | 4.123 | 4.493 | 0.281 | BS346 |

| MRT-045 | 4-1/4*4-5/8*3/16 | 4.248 | 4.618 | 0.281 | BS347 |

| MRT-046 | 4-3/8*4-3/4*3/16 | 4.373 | 4.743 | 0.281 | BS348 |

| MRT-047 | 4-1/2*4-7/8*3/16 | 4.498 | 4.868 | 0.281 | BS349 |

| MRT-048 | 5*5-1/2*1/4 | 4.997 | 5.471 | 0.375 | BS429 |

| MRT-049 | 5-1/4*5-3/4*1/4 | 5.247 | 5.721 | 0.375 | BS431 |

| MRT-050 | 5-1/2*6*1/4 | 5.497 | 5.971 | 0.375 | BS433 |

| MRT-051 | 5-5/8*6-1/8*1/4 | 5.622 | 6.096 | 0.375 | BS434 |

| MRT-052 | 6*6-1/2*1/4 | 5.997 | 6.471 | 0.375 | BS437 |

| MRT-053 | 6-1/4*6-3/4*1/4 | 6.247 | 6.721 | 0.375 | BS438 |

| MRT-054 | 6-1/2*7*1/4 | 6.497 | 6.971 | 0.375 | BS439 |

| MRT-055 | 6-3/4*7-1/4*1/4 | 6.747 | 7.221 | 0.375 | BS440 |

| MRT-056 | 7*7-1/2*1/4 | 6.997 | 7.471 | 0.375 | BS441 |

| MRT-057 | 7-1/4*7-3/4*1/4 | 7.247 | 7.721 | 0.375 | BS442 |

| MRT-058 | 7-1/2*8*1/4 | 7.497 | 7.971 | 0.375 | BS443 |

| MRT-059 | 8*8-1/2*1/4 | 7.997 | 8.471 | 0.375 | BS445 |

| MRT-060 | 9*9-1/2*1/4 | 8.997 | 9.471 | 0.375 | BS447 |

| MRT-061 | 9-1/2*10*1/4 | 9.497 | 9.971 | 0.375 | BS448 |

| MRT-062 | 10*10-1/2*1/4 | 9.997 | 10.471 | 0.375 | BS449 |

| MRT-063 | 11*11-1/2*1/4 | 10.997 | 11.471 | 0.375 | BS451 |

TSR profiles have a nitrile (NBR) rubber sealing element and hard polyamide anti-extrusion rings that lock into the rubber sealing element.

| Part No | Nom | (d) | (D) | (L) | O’ring Ref |

|---|---|---|---|---|---|

| TSR-204 | 3/8*5/8*1/8 | 0.373 | 0.615 | 0.187 | BS204 |

| TSR-206 | 1/2*3/4*1/8 | 0.498 | 0.740 | 0.187 | BS206 |

| TSR-207 | 9/16*13/16*1/8 | 0.560 | 0.802 | 0.187 | BS207 |

| TSR-208 | 5/8*7/8*1/8 | 0.623 | 0.865 | 0.187 | BS208 |

| TSR-209 | 11/16*15/16*1/8 | 0.685 | 0.927 | 0.187 | BS209 |

| TSR-210 | 3/4*1*1/8 | 0.748 | 0.990 | 0.187 | BS210 |

| TSR-212 | 7/8*1-1/8*1/8 | 0.873 | 1.115 | 0.187 | BS212 |

| TSR-214 | 1*1-1/4*1/8 | 0.998 | 1.240 | 0.187 | BS214 |

| TSR-215 | 1-1/16*1-5/16*1/8 | 1.060 | 1.302 | 0.187 | BS215 |

| TSR-216 | 1-1/8*1-3/8*1/8 | 1.123 | 1.365 | 0.187 | BS216 |

| TSR-217 | 1-3/16*1-7/16*1/8 | 1.185 | 1.427 | 0.187 | BS217 |

| TSR-218 | 1-1/4*1-1/2*1/8 | 1.248 | 1.490 | 0.187 | BS218 |

| TSR-220 | 1-3/8*1-5/8*1/8 | 1.373 | 1.615 | 0.187 | BS220 |

| TSR-221 | 1-7/16*1-11/16*1/8 | 1.435 | 1.677 | 0.187 | BS221 |

| TSR-222 | 1-1/2*1-3/4*1/8 | 1.498 | 1.740 | 0.187 | BS222 |

| TSR-325 | 1-1/2*1-7/8*3/16 | 1.498 | 1.868 | 0.281 | BS325 |

| TSR-326 | 1-5/8*2*3/16 | 1.625 | 1.993 | 0.281 | BS326 |

| TSR-327 | 1-3/4*2-1/8*3/16 | 1.748 | 2.118 | 0.281 | BS327 |

| TSR-328 | 1-7/8*2-1/4*3/16 | 1.873 | 2.243 | 0.281 | BS328 |

| TSR-329 | 2*2-3/8*3/16 | 1.998 | 2.368 | 0.281 | BS329 |

| TSR-330 | 2-1/8*2-1/2*3/16 | 2.123 | 2.493 | 0.281 | BS330 |

| TSR-331 | 2-1/4*2-5/8*3/16 | 2.248 | 2.618 | 0.281 | BS331 |

| TSR-332 | 2-3/8*2-3/4*3/16 | 2.373 | 2.743 | 0.281 | BS332 |

| TSR-333 | 2-1/2*2-7/8*3/16 | 2.498 | 2.868 | 0.281 | BS333 |

| TSR-334 | 2-5/8*3*3/16 | 2.623 | 2.993 | 0.281 | BS334 |

| TSR-335 | 2-3/4*3-1/8*3/16 | 2.748 | 3.118 | 0.281 | BS335 |

| TSR-336 | 2-7/8*3-1/4*3/16 | 2.873 | 3.243 | 0.281 | BS336 |

| TSR-337 | 3*3-3/8*3/16 | 2.998 | 3.368 | 0.281 | BS337 |

| TSR-338 | 3-1/8*3-1/2*3/16 | 3.123 | 3.493 | 0.281 | BS338 |

| TSR-339 | 3-1/4*3-5/8*3/16 | 3.248 | 3.618 | 0.281 | BS339 |

| TSR-340 | 3-3/8*3-3/4*3/16 | 3.373 | 3.743 | 0.281 | BS340 |

| TSR-341 | 3-1/2*3-7/8*3/16 | 3.498 | 3.868 | 0.281 | BS341 |

| TSR-342 | 3-5/8*4*3/16 | 3.623 | 3.993 | 0.281 | BS342 |

| TSR-343 | 3-3/4*4-1/8*3/16 | 3.748 | 4.118 | 0.281 | BS343 |

| TSR-344 | 3-7/8*4-1/4*3/16 | 3.873 | 4.243 | 0.281 | BS344 |

| TSR-345 | 4*4-3/8*3/16 | 3.998 | 4.368 | 0.281 | BS345 |

| TSR-347 | 4-1/4*4-5/8*3/16 | 4.248 | 4.618 | 0.281 | BS347 |

| TSR-349 | 4-1/2*4-7/8*3/16 | 4.498 | 4.868 | 0.281 | BS349 |

| TSR-429 | 5*5-1/2*1/4 | 4.997 | 5.471 | 0.375 | BS429 |

| TSR-433 | 5-1/2*6*1/4 | 5.497 | 5.971 | 0.375 | BS433 |

| TSR-436 | 5-7/8*6-3/8*1/4 | 5.873 | 6.423 | 0.375 | BS433 |

| TSR-437 | 6*6-1/2*1/4 | 5.997 | 6.471 | 0.375 | BS437 |

| TSR-439 | 6-1/2*7*1/4 | 6.497 | 6.971 | 0.375 | BS439 |

| TSR-441 | 7*7-1/2*1/4 | 6.997 | 7.471 | 0.375 | BS441 |

| TSR-447 | 9*9-1/2*1/4 | 8.997 | 9.471 | 0.375 | BS447 |