Hydraulic cylinders operate in a variety of applications and environmental conditions, including exposure to dust, debris and outside weather conditions.

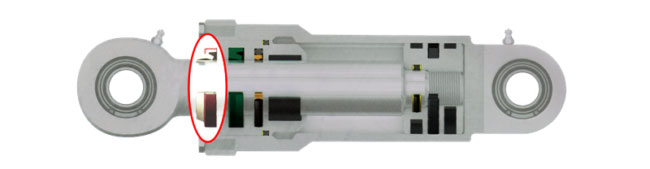

Hydraulic cylinders operate in a variety of applications and environmental conditions, including exposure to dust, debris and outside weather conditions. To prevent these contaminates from entering the cylinder assembly and hydraulic system, wiper seals (also known as scrapers, excluders or dust seals) are fitted on the external side of the cylinder head.

Wiper seals maintain sealing contact to the piston rod when the equipment is stationary and in use. Without a wiper seal, the retracting piston rod could transport contaminates into the cylinder which can adversely affect performance and service life of hydraulic systems.

The outside static sealing of the wiper within the groove is also important to avoid moisture or particles from entering the system around the outside of the wiper seal. Sealing Australia stocks a comprehensive range of rod wipers.

Use the links below to jump to that section.

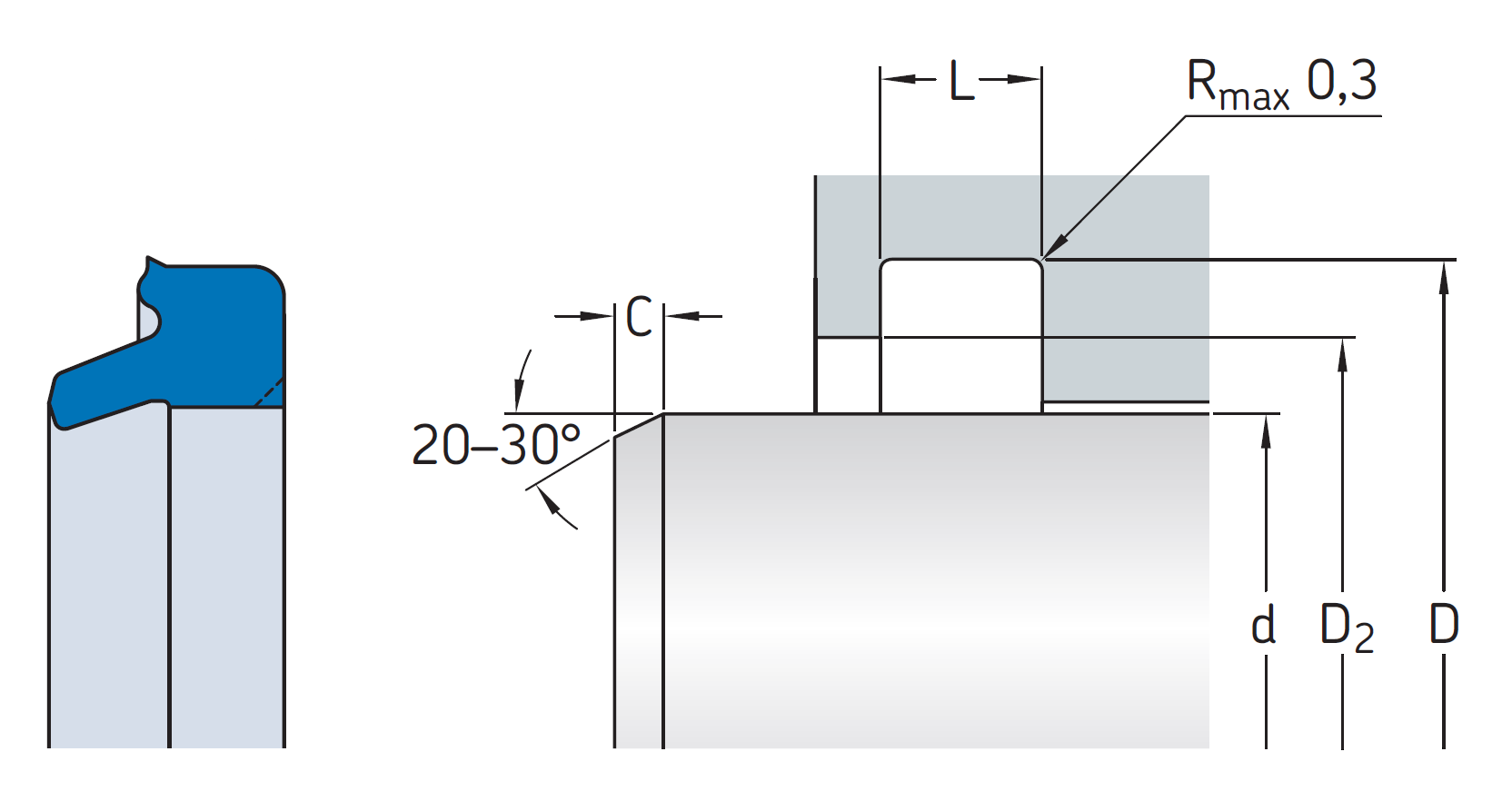

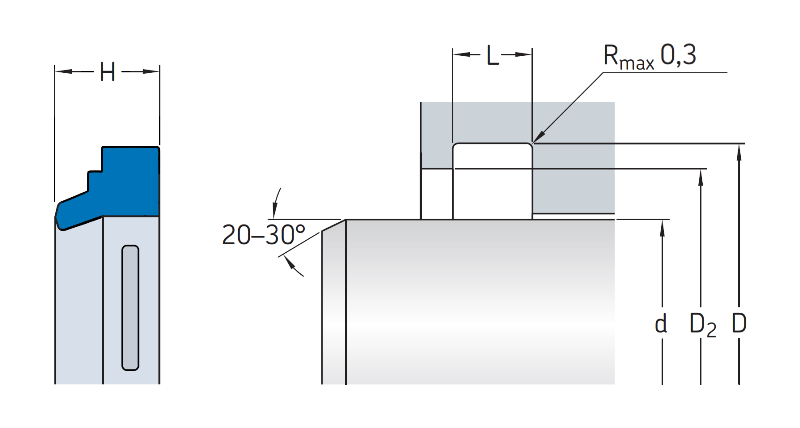

Material: TPU

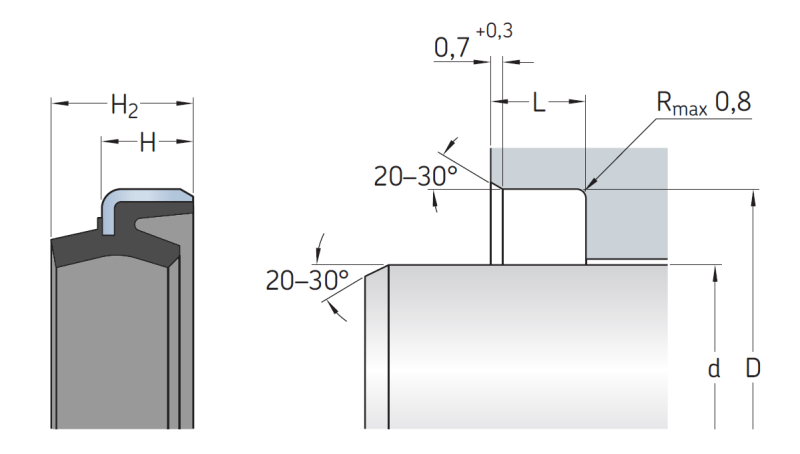

Groove: ISO 6195 Type A

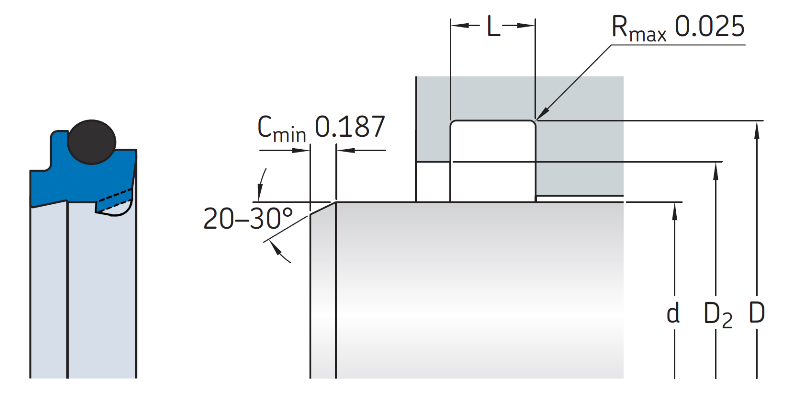

DTW rod wipers are a D-style single lip, snap-in design with a radial static sealing lip on the outside surface that maintains a positive sealing contact. An axial static seal lip on the external top side of the heel keeps the wiper tight in the groove and also serves as an additional static seal to prevent the ingress dust and contaminates around the outside of the seal. DTW wipers feature a slotted heel; vents on the inside edge to prevent the wiper trapping pressure or being pushed out by pressure in the event the rod seal has become damaged or has exceeded its service life. DTW wipers are currently available in metric sizes. For imperial, please see DSW rod wipers. For sizes not found in the DTW range, please check our SQW range

| Part No | (d) ±f7 | (D) ±H9 | (L) +0.25 | (D₂) | (C) min |

|---|---|---|---|---|---|

| DTW-18*26*5 | 18.0 | 26.0 | 5.0 | 22.0 | 4.5 |

| DTW-20*28*5 | 20.0 | 28.0 | 5.0 | 24.0 | 4.5 |

| DTW-22*30*5 | 22.0 | 30.0 | 5.0 | 26.0 | 4.5 |

| DTW-25*33*5 | 25.0 | 33.0 | 5.0 | 29.0 | 4.5 |

| DTW-28*36*5 | 28.0 | 36.0 | 5.0 | 32.0 | 4.5 |

| DTW-30*38*5 | 30.0 | 38.0 | 5.0 | 34.0 | 4.5 |

| DTW-32*40*5 | 32.0 | 40.0 | 5.0 | 36.0 | 4.5 |

| DTW-32*40*6 | 32.0 | 40.0 | 6.0 | 36.0 | 4.5 |

| DTW-35*43*6 | 35.0 | 43.0 | 6.0 | 39.0 | 4.5 |

| DTW-40*48*5 | 40.0 | 48.0 | 5.0 | 44.0 | 4.5 |

| DTW-40*48*6 | 40.0 | 48.0 | 6.0 | 44.0 | 4.5 |

| DTW-45*53*6 | 45.0 | 53.0 | 6.0 | 49.0 | 4.5 |

| DTW-50*58*5 | 50.0 | 58.0 | 5.0 | 54.0 | 4.5 |

| DTW-50*58*6 | 50.0 | 58.0 | 6.0 | 54.0 | 4.5 |

| DTW-55*63*6 | 55.0 | 63.0 | 6.0 | 59.0 | 4.5 |

| DTW-55*65*7 | 55.0 | 65.0 | 7.0 | 60.0 | 5.0 |

| DTW-56*64*6 | 56.0 | 64.0 | 6.0 | 60.0 | 4.5 |

| DTW-60*68*6 | 60.0 | 68.0 | 6.0 | 64.0 | 4.5 |

| DTW-60*70*7 | 60.0 | 70.0 | 7.0 | 65.0 | 5.0 |

| DTW-63*71*6 | 63.0 | 71.0 | 6.0 | 67.0 | 4.5 |

| DTW-65*73*6 | 65.0 | 73.0 | 6.0 | 69.0 | 4.5 |

| DTW-65*75*7 | 65.0 | 75.0 | 7.0 | 70.0 | 5.0 |

| DTW-70*80*7 | 70.0 | 80.0 | 7.0 | 75.0 | 5.0 |

| DTW-71*81*7 | 71.0 | 81.0 | 7.0 | 76.0 | 5.0 |

| DTW-75*85*7 | 75.0 | 85.0 | 7.0 | 80.0 | 5.0 |

| DTW-80*90*7 | 80.0 | 90.0 | 7.0 | 85.0 | 5.0 |

| DTW-85*95*7 | 85.0 | 95.0 | 7.0 | 90.0 | 5.0 |

| DTW-90*100*7 | 90.0 | 100.0 | 7.0 | 95.0 | 5.0 |

| DTW-95*105*7 | 95.0 | 105.0 | 7.0 | 100.0 | 5.0 |

| DTW-100*110*7 | 100.0 | 110.0 | 7.0 | 105.0 | 5.0 |

| DTW-105*115*7 | 105.0 | 115.0 | 7.0 | 110.0 | 5.0 |

| DTW-110*120*7 | 110.0 | 120.0 | 7.0 | 115.0 | 5.0 |

| DTW-112*122*7 | 112.0 | 122.0 | 7.0 | 117.0 | 5.0 |

| DTW-115*125*7 | 115.0 | 125.0 | 7.0 | 120.0 | 5.0 |

| DTW-120*130*7 | 120.0 | 130.0 | 7.0 | 125.0 | 5.0 |

| DTW-125*138*8 | 125.0 | 138.0 | 8.0 | 132.0 | 5.5 |

| DTW-130*143*8 | 130.0 | 143.0 | 8.0 | 137.0 | 5.5 |

| DTW-140*153*8 | 140.0 | 153.0 | 8.0 | 147.0 | 5.5 |

| DTW-145*158*8 | 145.0 | 158.0 | 8.0 | 152.0 | 5.5 |

| DTW-150*163*8 | 150.0 | 163.0 | 8.0 | 157.0 | 5.5 |

| DTW-160*173*8 | 160.0 | 173.0 | 8.0 | 167.0 | 5.5 |

| DTW-160*174*8 | 160.0 | 174.0 | 8.0 | 167.0 | 6.0 |

| DTW-170*183*8 | 170.0 | 183.0 | 8.0 | 177.0 | 5.5 |

| DTW-170*184*8 | 170.0 | 184.0 | 8.0 | 177.0 | 6.0 |

| DTW-180*194*8 | 180.0 | 194.0 | 8.0 | 187.0 | 6.0 |

| DTW-200-213-8 | 200.0 | 213.0 | 8.0 | 207.0 | 5.5 |

| DTW-200-214-8 | 200.0 | 214.0 | 8.0 | 207.0 | 6.0 |

| DTW-230*244*8 | 230.0 | 244.0 | 8.0 | 237.0 | 6.0 |

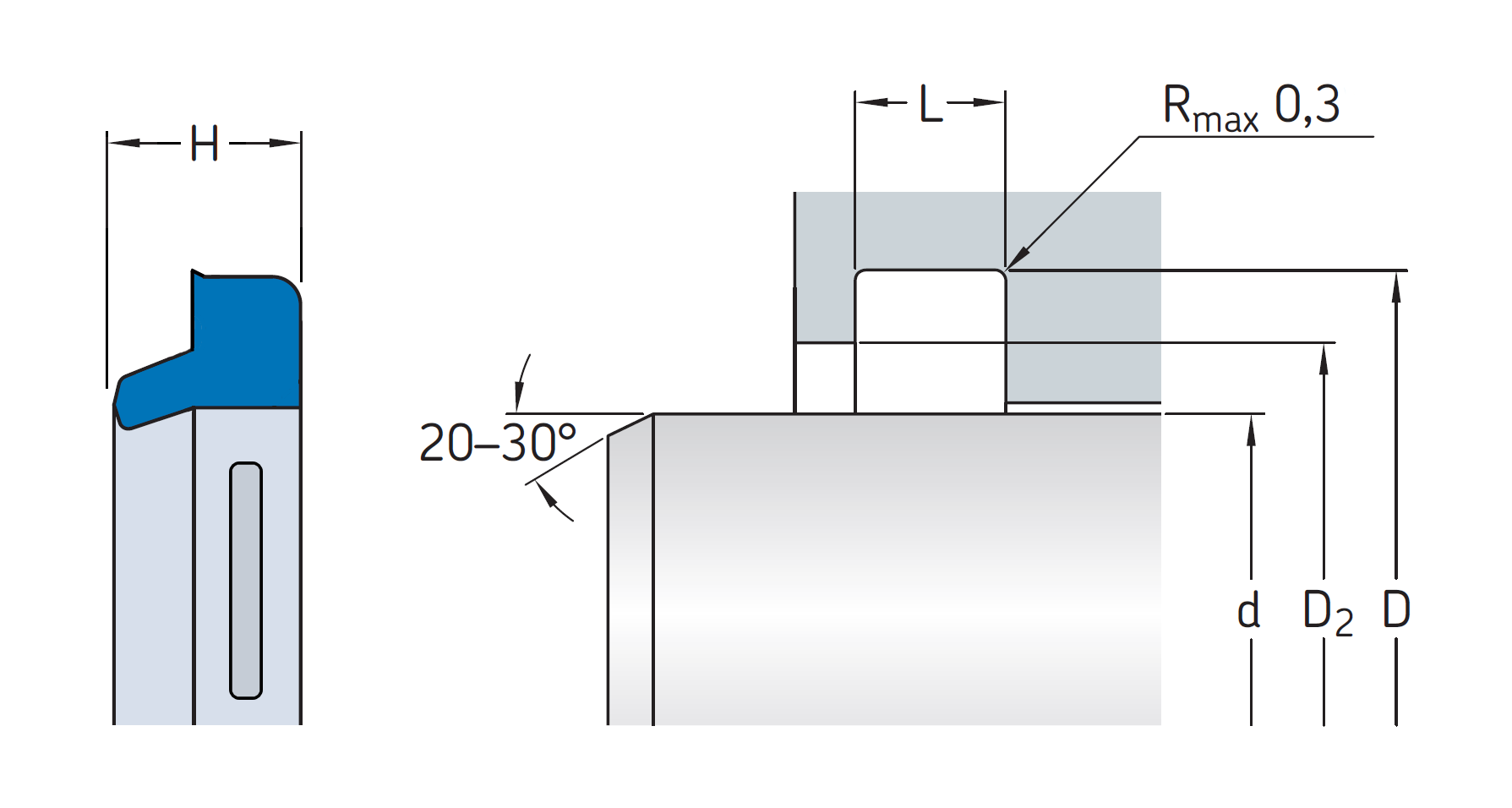

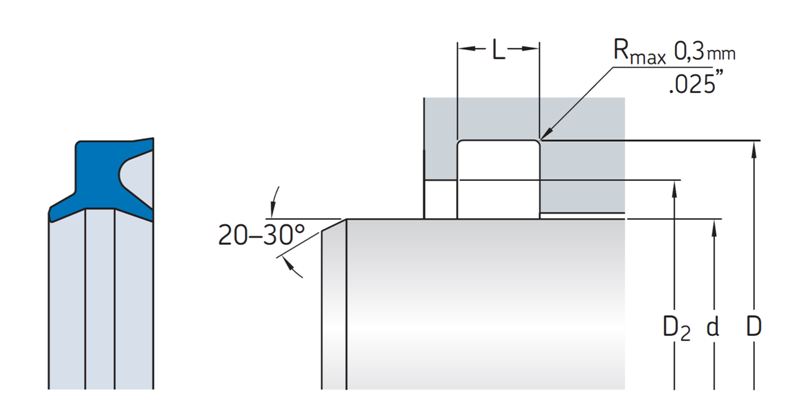

Material: TPU

Groove: ISO 6195 Type A

SQW rod wipers are a medium duty single lip snap-in design with a square shoulder. SQW wipers feature pressure relief ridges on the inside of the heel that prevent the wiper trapping pressure or being pushed out by pressure in the event the rod seal has become damaged or has exceeded its service life. Most sizes feature a secondary outside lip to prevent the ingress of dust and contaminates from around the outside of the seal. SQW wipers are available in metric sizes. For sizes not found in the SQW range, please check our DTW range.

| Part No | (d) ±f7 | (D) ±H9 | (L) +0.25 | (H) | (D₂) +0.25 |

|---|---|---|---|---|---|

| SQW-5*12*2.8 | 5.0 | 12.0 | 2.8 | 4.0 | 9.0 |

| SQW-8*14.6*3.8 | 8.0 | 14.6 | 3.8 | 4.5 | 11.0 |

| SQW-12*18.6*3.8 | 12.0 | 18.6 | 3.8 | 5.0 | 15.0 |

| SQW-14*20.6*3.8 | 14.0 | 20.6 | 3.8 | 5.0 | 17.0 |

| SQW-15*27*5 | 15.0 | 27.0 | 5.0 | 7.0 | 18.5 |

| SQW-16*22.6*3.9 | 16.0 | 22.6 | 3.9 | 5.0 | 19.0 |

| SQW-16*24.6*5.3 | 16.0 | 24.6 | 5.3 | 7.0 | 19.0 |

| SQW-18*24.6*3.8 | 18.0 | 24.6 | 3.8 | 5.0 | 21.0 |

| SQW-20*30*5 | 20.0 | 30.0 | 5.0 | 7.0 | 25.0 |

| SQW-24*32*2 | 24.0 | 32.0 | 2.0 | 3.5 | 27.0 |

| SQW-24*32*5 | 24.0 | 32.0 | 5.0 | 7.0 | 27.0 |

| SQW-35*43.6*5.3 | 35.0 | 43.6 | 5.3 | 7.0 | 38.0 |

| SQW-36*44.6*5.3 | 36.0 | 44.6 | 5.3 | 7.0 | 39.0 |

| SQW-42*50.6*5.3 | 42.0 | 50.6 | 5.3 | 7.0 | 45.0 |

| SQW-45*53.6*5.3 | 45.0 | 53.6 | 5.3 | 7.0 | 48.0 |

| SQW-45*55.6*5.3 | 45.0 | 55.6 | 5.3 | 7.0 | 48.0 |

| SQW-45*60*4 | 45.0 | 60.0 | 4.0 | 6.0 | 53.0 |

| SQW-46*54*5 | 46.0 | 54.0 | 5.0 | 7.0 | 49.0 |

| SQW-50*60.6*5.3 | 50.0 | 60.6 | 5.3 | 7.0 | 53.0 |

| SQW-50*65.6*4.3 | 50.0 | 65.6 | 4.3 | 6.0 | 58.0 |

| SQW-53*61.6*5.3 | 53.0 | 61.6 | 5.3 | 7.0 | 56.0 |

| SQW-55*63.6*5.3 | 55.0 | 63.6 | 5.3 | 7.0 | 58.0 |

| SQW-55*65.6*5.3 | 55.0 | 65.6 | 5.3 | 7.0 | 58.0 |

| SQW-56*66.6*5.3 | 56.0 | 66.6 | 5.3 | 7.0 | 59.0 |

| SQW-60*68.6*5.3 | 60.0 | 68.6 | 5.3 | 7.0 | 63.0 |

| SQW-60*70.6*5.5 | 60.0 | 70.6 | 5.5 | 7.0 | 63.0 |

| SQW-61*69*5 | 61.0 | 69.0 | 5.0 | 7.0 | 64.0 |

| SQW-63*71.6*5.3 | 63.0 | 71.6 | 5.3 | 7.0 | 66.0 |

| SQW-63*73.6*5.3 | 63.0 | 73.6 | 5.3 | 7.0 | 66.0 |

| SQW-65*73.6*5.3 | 65.0 | 73.6 | 5.3 | 7.0 | 68.0 |

| SQW-65*75.6*5.3 | 65.0 | 75.6 | 5.3 | 7.0 | 68.0 |

| SQW-65*76.6*6 | 65.0 | 76.6 | 6.0 | 7.0 | 71.5 |

| SQW-70*78.6*5.3 | 70.0 | 78.6 | 5.3 | 7.0 | 73.0 |

| SQW-70*80.6*5.3 | 70.0 | 80.6 | 5.3 | 7.0 | 73.0 |

| SQW-70*82.6*7.2 | 70.0 | 82.6 | 7.2 | 12.0 | 76.0 |

| SQW-73*81.6*5.3 | 73.0 | 81.6 | 5.3 | 7.0 | 76.0 |

| SQW-73*83.6*7.2 | 73.0 | 83.6 | 7.2 | 12.0 | 76.0 |

| SQW-75*83.2*5.3 | 75.0 | 83.2 | 5.3 | 7.0 | 78.0 |

| SQW-75*87.2*7.2 | 75.0 | 87.2 | 7.2 | 12.0 | 81.0 |

| SQW-76*84*5 | 76.0 | 84.0 | 5.0 | 7.0 | 81.0 |

| SQW-78*88.6*5.5 | 78.0 | 88.6 | 5.5 | 7.0 | 84.5 |

| SQW-78*92.2*7.2 | 78.0 | 92.2 | 7.2 | 12.0 | 85.0 |

| SQW-80*88.6*5.3 | 80.0 | 88.6 | 5.3 | 7.0 | 83.0 |

| SQW-80*90*6 | 80.0 | 90.0 | 6.0 | 9.0 | 83.0 |

| SQW-80*92.2*7.2 | 80.0 | 92.2 | 7.2 | 12.0 | 86.0 |

| SQW-85*93.6*5.3 | 85.0 | 93.6 | 5.3 | 7.0 | 88.0 |

| SQW-85*97.2*7.2 | 85.0 | 97.2 | 7.2 | 12.0 | 91.0 |

| SQW-90*102.2*6 | 90.0 | 102.2 | 6.0 | 8.0 | 94.0 |

| SQW-90*102.2*7.2 | 90.0 | 102.2 | 7.2 | 12.0 | 96.0 |

| SQW-91*99*5 | 91.0 | 99.0 | 5.0 | 7.0 | 94.0 |

| SQW-95*103*5 | 95.0 | 103.0 | 5.0 | 7.0 | 98.0 |

| SQW-95*107.2*7.2 | 95.0 | 107.2 | 7.2 | 12.0 | 101.0 |

| SQW-97*105*5 | 97.0 | 105.0 | 5.0 | 7.0 | 100.0 |

| SQW-100*112.2*7.2 | 100.0 | 112.2 | 7.2 | 12.0 | 106.0 |

| SQW-100*115*9.2 | 100.0 | 115.0 | 9.2 | 13.0 | 110.0 |

| SQW-105*117.2*7.2 | 105.0 | 117.2 | 7.2 | 12.0 | 111.0 |

| SQW-107*115*5 | 107.0 | 115.0 | 5.0 | 7.0 | 110.0 |

| SQW-110*122.2*7.2 | 110.0 | 122.2 | 7.2 | 12.0 | 116.0 |

| SQW-110*125*9.5 | 110.0 | 125.0 | 9.5 | 14.0 | 118.0 |

| SQW-115*127.2*7.2 | 115.0 | 127.2 | 7.2 | 12.0 | 121.0 |

| SQW-118*126*5 | 118.0 | 126.0 | 5.0 | 7.0 | 121.0 |

| SQW-120*132.2*7.2 | 120.0 | 132.2 | 7.2 | 12.0 | 126.0 |

| SQW-125*133*5 | 125.0 | 133.0 | 5.0 | 7.0 | 128.0 |

| SQW-125*137.6*7.2 | 125.0 | 137.6 | 7.2 | 12.0 | 131.0 |

| SQW-125*140*10.2 | 125.0 | 140.0 | 10.2 | 16.0 | 132.5 |

| SQW-126*134*5 | 126.0 | 134.0 | 5.0 | 7.0 | 129.0 |

| SQW-128*140.2*7.2 | 128.0 | 140.2 | 7.2 | 12.0 | 134.0 |

| SQW-135*147*7.2 | 135.0 | 147.0 | 7.2 | 12.0 | 141.0 |

| SQW-140*155*10.2 | 140.0 | 155.0 | 10.2 | 16.0 | 147.5 |

| SQW-143*151*5.5 | 143.0 | 151.0 | 5.5 | 7.0 | 146.0 |

| SQW-145*153*5 | 145.0 | 153.0 | 5.0 | 7.0 | 148.0 |

| SQW-145*157.2*7.2 | 145.0 | 157.2 | 7.2 | 12.0 | 151.0 |

| SQW-145*160*9 | 145.0 | 160.0 | 9.0 | 16.0 | 155.0 |

| SQW-150*162*7.2 | 150.0 | 162.0 | 7.2 | 12.0 | 156.0 |

| SQW-150*165*10.2 | 150.0 | 165.0 | 10.2 | 16.0 | 157.5 |

| SQW-160*172*7.2 | 160.0 | 172.0 | 7.2 | 12.0 | 166.0 |

| SQW-160*175*10.2 | 160.0 | 175.0 | 10.2 | 16.0 | 167.5 |

| SQW-163*175*7 | 163.0 | 175.0 | 7.0 | 12.0 | 169.0 |

| SQW-170*180*5 | 170.0 | 180.0 | 5.0 | 7.0 | 174.0 |

| SQW-170*182*7 | 170.0 | 182.0 | 7.0 | 12.0 | 176.0 |

| SQW-170*185*10.2 | 170.0 | 185.0 | 10.2 | 16.0 | 177.5 |

| SQW-180*188*5 | 180.0 | 188.0 | 5.0 | 7.0 | 183.0 |

| SQW-180*195*9.2 | 180.0 | 195.0 | 9.2 | 14.0 | 190.0 |

| SQW-180*200*10.2 | 180.0 | 200.0 | 10.2 | 18.0 | 190.0 |

| SQW-200*215.2*10.2 | 200.0 | 215.2 | 10.2 | 16.0 | 208.0 |

| SQW-200*220*10.2 | 200.0 | 220.0 | 10.2 | 18.0 | 210.0 |

| SQW-210*225.2*10.2 | 210.0 | 225.2 | 10.2 | 16.0 | 218.0 |

| SQW-220*240*10 | 220.0 | 240.0 | 10.0 | 16.0 | 230.0 |

| SQW-240*255.2*10.2 | 240.0 | 255.2 | 10.2 | 16.0 | 248.0 |

| SQW-280*300*10.2 | 280.0 | 300.0 | 10.2 | 18.0 | 290.0 |

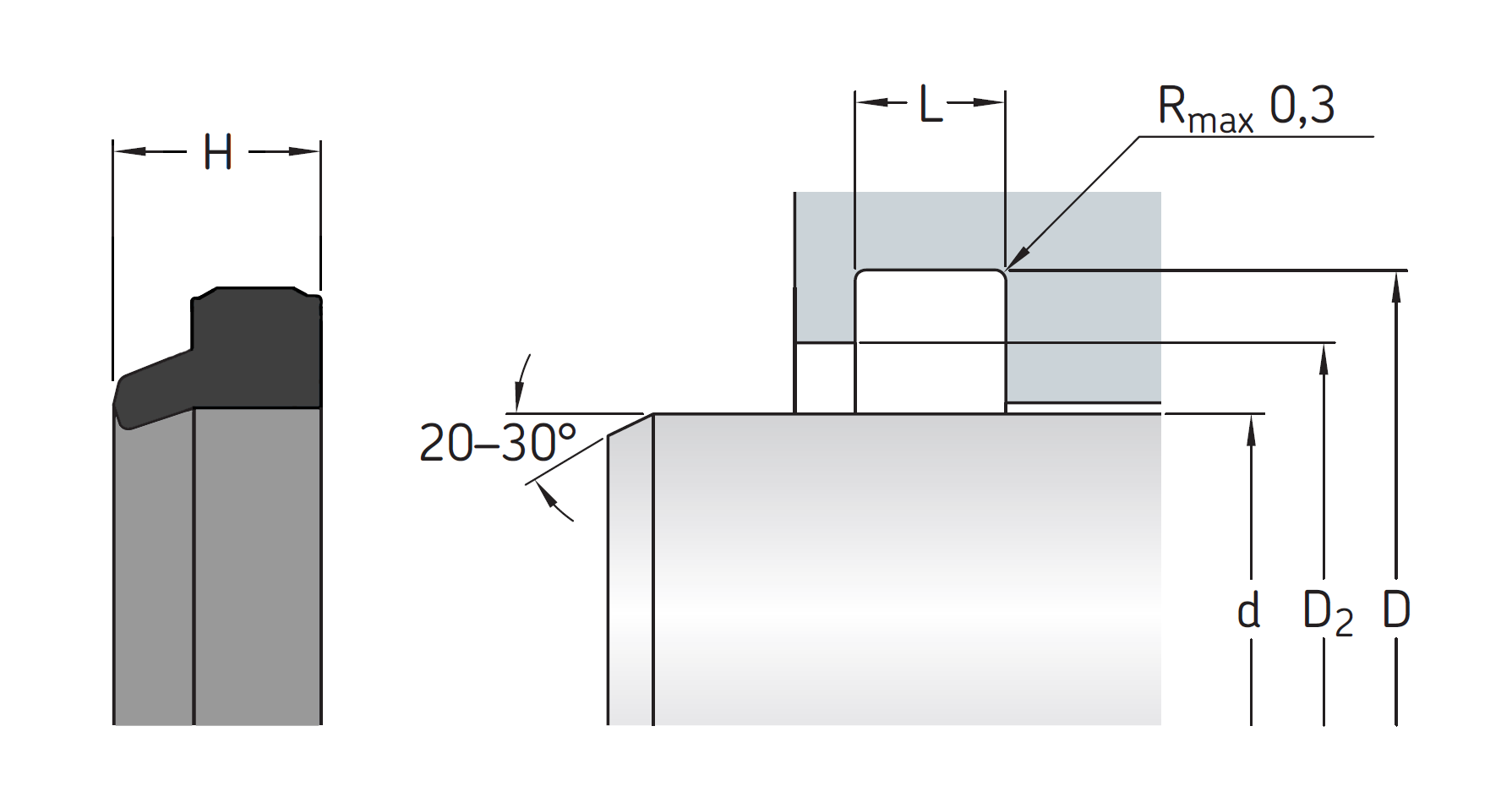

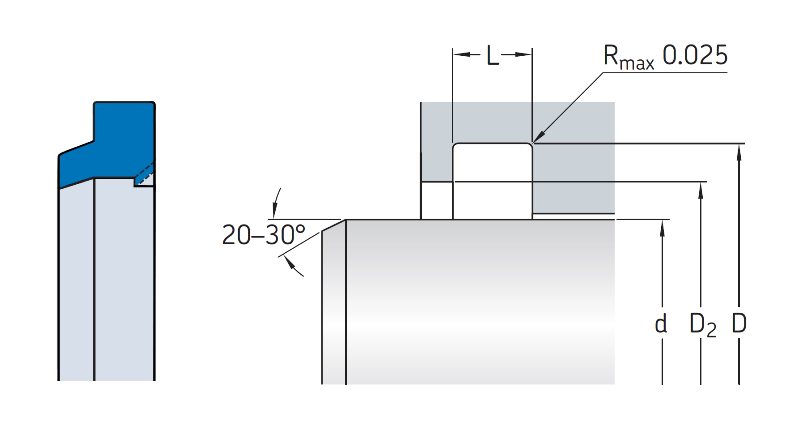

Material: NBR

Groove: ISO 6195 Type A

DSI rod wipers are a light to medium duty single lip snap-in design with a simple square shoulder. One of the most common styles found hydraulics and pneumatics, this metric D-style wiper can be ordered in many different rubber compounds including XNBR, FKM, EPDM as well as food grade compounds, please contact us for more information.

| Part No | (d) ±f7 | (D) ±H9 | (L) +0.25 | (H) | (D₂) |

|---|---|---|---|---|---|

| DSI-12*18*3.5/5 | 12.0 | 18.0 | 3.8 | 5.0 | 15.0 |

| DSI-13*19*3.5/5 | 12.0 | 19.0 | 3.8 | 5.0 | 16.0 |

| DSI-14*21*3.5/5 | 14.0 | 21.0 | 3.8 | 5.0 | 18.0 |

| DSI-15*21*3.5/5 | 15.0 | 21.0 | 3.8 | 5.0 | 18.0 |

| DSI-16*22*3.5/5 | 16.0 | 22.0 | 3.8 | 5.0 | 19.0 |

| DSI-17*23*3.5/5 | 17.0 | 23.0 | 3.8 | 5.0 | 20.0 |

| DSI-18*24*3.5/5 | 18.0 | 24.0 | 3.8 | 5.0 | 21.0 |

| DSI-19*28*5/7 | 19.0 | 28.0 | 5.3 | 7.0 | 22.0 |

| DSI-20*28*5/7 | 20.0 | 28.0 | 5.3 | 7.0 | 23.0 |

| DSI-22*30*5/7 | 22.0 | 30.0 | 5.3 | 7.0 | 25.0 |

| DSI-24*32*5/7 | 24.0 | 32.0 | 5.3 | 7.0 | 27.0 |

| DSI-25*33*5/7 | 25.0 | 33.0 | 5.3 | 7.0 | 28.0 |

| DSI-26*34*5/7 | 26.0 | 34.0 | 5.3 | 7.0 | 29.0 |

| DSI-27*35*5/7 | 27.0 | 35.0 | 5.3 | 7.0 | 30.0 |

| DSI-28*36*5/7 | 28.0 | 36.0 | 5.3 | 7.0 | 31.0 |

| DSI-30*38*5/7 | 30.0 | 38.0 | 5.3 | 7.0 | 33.0 |

| DSI-32*40*5/7 | 32.0 | 40.0 | 5.3 | 7.0 | 35.0 |

| DSI-33*41*5/7 | 33.0 | 41.0 | 5.3 | 7.0 | 36.0 |

| DSI-35*43*5/7 | 35.0 | 43.0 | 5.3 | 7.0 | 38.0 |

| DSI-36*44*5/7 | 36.0 | 44.0 | 5.3 | 7.0 | 39.0 |

| DSI-38*46*5/7 | 38.0 | 46.0 | 5.3 | 7.0 | 41.0 |

| DSI-40*48*5/7 | 40.0 | 48.0 | 5.3 | 7.0 | 43.0 |

| DSI-42*50*5/7 | 42.0 | 50.0 | 5.3 | 7.0 | 45.0 |

| DSI-45*53*5/7 | 45.0 | 53.0 | 5.3 | 7.0 | 48.0 |

| DSI-45*55*5/7 | 45.0 | 55.0 | 5.3 | 7.0 | 48.0 |

| DSI-46*54*5/7 | 46.0 | 54.0 | 5.3 | 7.0 | 49.0 |

| DSI-48*56*5/7 | 48.0 | 56.0 | 5.3 | 7.0 | 51.0 |

| DSI-50*58*5/7 | 50.0 | 58.0 | 5.3 | 7.0 | 53.0 |

| DSI-50*60*5/7 | 50.0 | 60.0 | 5.3 | 7.0 | 53.0 |

| DSI-53*61*5/7 | 53.0 | 61.0 | 5.3 | 7.0 | 56.0 |

| DSI-55*63*5/7 | 55.0 | 63.0 | 5.3 | 7.0 | 58.0 |

| DSI-55*65*5/7 | 55.0 | 65.0 | 5.3 | 7.0 | 58.0 |

| DSI-56*64*5/7 | 56.0 | 64.0 | 5.3 | 7.0 | 59.0 |

| DSI-56*66*5/7 | 56.0 | 66.0 | 5.3 | 7.0 | 59.0 |

| DSI-60*68*5/7 | 60.0 | 68.0 | 5.3 | 7.0 | 63.0 |

| DSI-60*70*5/7 | 60.0 | 70.0 | 5.3 | 7.0 | 63.0 |

| DSI-63*73*5/7 | 63.0 | 73.0 | 5.3 | 7.0 | 66.0 |

| DSI-65*73*5/7 | 65.0 | 73.0 | 5.3 | 7.0 | 68.0 |

| DSI-65*75*5/7 | 65.0 | 75.0 | 5.3 | 7.0 | 68.0 |

| DSI-70*78*5/7 | 70.0 | 78.0 | 5.3 | 7.0 | 73.0 |

| DSI-70*80*5/7 | 70.0 | 80.0 | 5.3 | 7.0 | 73.0 |

| DSI-70*82*7/12 | 70.0 | 82.0 | 7.1 | 12.0 | 76.0 |

| DSI-73*81*5/7 | 73.0 | 81.0 | 5.3 | 7.0 | 76.0 |

| DSI-75*83*5/7 | 75.0 | 83.0 | 5.3 | 7.0 | 78.0 |

| DSI-75*87*7/12 | 75.0 | 87.0 | 7.1 | 12.0 | 81.0 |

| DSI-78*92*7/12 | 78.0 | 92.0 | 7.1 | 12.0 | 85.0 |

| DSI-80*88*5/7 | 80.0 | 88.0 | 5.3 | 7.0 | 83.0 |

| DSI-80*92*7/12 | 80.0 | 92.0 | 7.1 | 12.0 | 86.0 |

| DSI-83*91*5/7 | 83.0 | 91.0 | 5.3 | 7.0 | 86.0 |

| DSI-85*93*5/7 | 85.0 | 93.0 | 5.3 | 7.0 | 88.0 |

| DSI-85*97*7/12 | 85.0 | 97.0 | 7.1 | 12.0 | 91.0 |

| DSI-88*100*7/12 | 88.0 | 100.0 | 7.1 | 12.0 | 94.0 |

| DSI-90*102*7/12 | 90.0 | 102.0 | 7.1 | 12.0 | 96.0 |

| DSI-95*107*7/12 | 95.0 | 107.0 | 7.1 | 12.0 | 101.0 |

| DSI-100*112*7/12 | 100.0 | 112.0 | 7.1 | 12.0 | 106.0 |

| DSI-105*117*7/12 | 105.0 | 117.0 | 7.1 | 12.0 | 111.0 |

| DSI-110*122*7/12 | 110.0 | 122.0 | 7.1 | 12.0 | 116.0 |

| DSI-115*127*7/12 | 115.0 | 127.0 | 7.1 | 12.0 | 121.0 |

| DSI-120*132*7/12 | 120.0 | 132.0 | 7.1 | 12.0 | 126.0 |

| DSI-125*137*7/12 | 125.0 | 137.0 | 7.1 | 12.0 | 131.0 |

| DSI-125*140*10/16 | 125.0 | 140.0 | 10.1 | 16.0 | 132.6 |

| DSI-130*142*7/12 | 130.0 | 142.0 | 7.1 | 12.0 | 136.0 |

| DSI-135*147*7/12.5 | 135.0 | 147.0 | 7.1 | 12.5 | 141.0 |

| DSI-140*155*10/16 | 140.0 | 155.0 | 10.1 | 16.0 | 147.6 |

| DSI-145*157*7/12.5 | 145.0 | 157.0 | 7.1 | 12.5 | 151.0 |

| DSI-150*165*10/16 | 150.0 | 165.0 | 10.1 | 16.0 | 157.6 |

| DSI-160*175*10/16 | 160.0 | 175.0 | 10.1 | 16.0 | 167.6 |

| DSI-170*185*10/16 | 170.0 | 185.0 | 10.1 | 16.0 | 178.0 |

| DSI-180*195*10/16 | 180.0 | 195.0 | 10.1 | 16.0 | 188.0 |

| DSI-180*200*10/18 | 180.0 | 200.0 | 10.2 | 18.0 | 190.0 |

| DSI-200*220*10/18 | 200.0 | 220.0 | 10.2 | 18.0 | 210.0 |

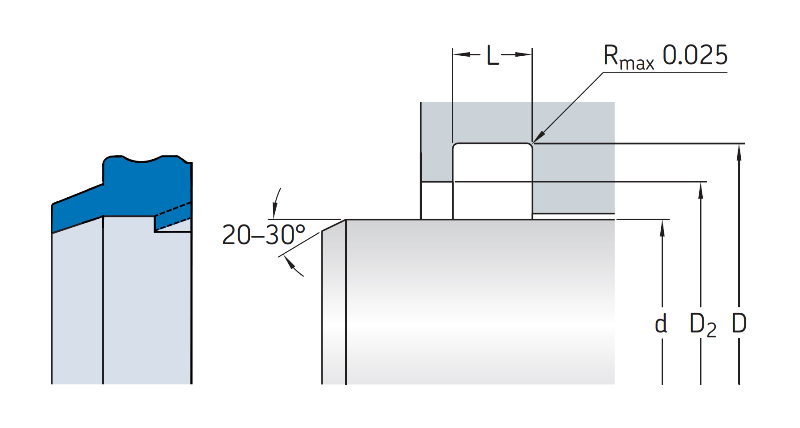

Material: TPU

Groove: ISO 6195 Type E

STW rod wipers are a light-duty single lip snap-in design with a double-stepped shoulder to firmly secure the wiper within the groove. STW wipers feature pressure relief ridges on the inside of the heel that prevent the wiper trapping pressure or being pushed out of the groove by pressure in the event the rod seal has become damaged or has exceeded its service life. STW wipers are available in metric sizes.

| Part No | (d) ±f7 | (D) ±H9 | (L) +0.25 | (D₂) +0.25 | (H) |

|---|---|---|---|---|---|

| STW-10*18*16*4/7 | 10.0 | 18.0 | 4.0 | 16.0 | 7.0 |

| STW-12*20*18*4/7 | 12.0 | 20.0 | 4.0 | 18.0 | 7.0 |

| STW-15*23*21*4/7 | 15.0 | 23.0 | 4.0 | 21.0 | 7.0 |

| STW-18*26*24*4/7 | 18.0 | 24.0 | 4.0 | 24.0 | 7.0 |

| STW-20*28*26*4/7 | 20.0 | 28.0 | 4.0 | 26.0 | 7.0 |

| STW-22*30*28*4/7 | 22.0 | 30.0 | 4.0 | 28.0 | 7.0 |

| STW-24*32*30*4/7 | 24.0 | 32.0 | 4.0 | 30.0 | 7.0 |

| STW-25*33*31*4/7 | 25.0 | 33.0 | 4.0 | 31.0 | 7.0 |

| STW-26*34*32*4/7 | 26.0 | 34.0 | 4.0 | 32.0 | 7.0 |

| STW-28*36*34*4/7 | 28.0 | 36.0 | 4.0 | 34.0 | 7.0 |

| STW-30*38*36*4/7 | 30.0 | 38.0 | 4.0 | 36.0 | 7.0 |

| STW-32*40*38*4/7 | 32.0 | 40.0 | 4.0 | 38.0 | 7.0 |

| STW-35*43*41*4/7 | 35.0 | 43.0 | 4.0 | 41.0 | 7.0 |

| STW-36*44*42*4/7 | 36.0 | 44.0 | 4.0 | 42.0 | 7.0 |

| STW-38*46*44*4/7 | 38.0 | 46.0 | 4.0 | 44.0 | 7.0 |

| STW-40*48*46*4/7 | 40.0 | 48.0 | 4.0 | 46.0 | 7.0 |

| STW-42*50*48*4/7 | 42.0 | 50.0 | 4.0 | 48.0 | 7.0 |

| STW-45*53*51*4/7 | 45.0 | 53.0 | 4.0 | 51.0 | 7.0 |

| STW-50*58*56*4/7 | 50.0 | 58.0 | 4.0 | 56.0 | 7.0 |

| STW-55*63*61*4/7 | 55.0 | 63.0 | 4.0 | 61.0 | 7.0 |

| STW-56*64*62*4/7 | 56.0 | 64.0 | 4.0 | 62.0 | 7.0 |

| STW-60*68*66*4/7 | 60.0 | 68.0 | 4.0 | 66.0 | 7.0 |

| STW-63*71*69*4/7 | 63.0 | 71.0 | 4.0 | 69.0 | 7.0 |

| STW-65*73*71*4/7 | 65.0 | 73.0 | 4.0 | 71.0 | 7.0 |

| STW-70*78*76*4/7 | 70.0 | 78.0 | 4.0 | 76.0 | 7.0 |

| STW-75*83*81*4/7 | 75.0 | 83.0 | 4.0 | 81.0 | 7.0 |

| STW-80*88*86*4/7 | 80.0 | 88.0 | 4.0 | 86.0 | 7.0 |

| STW-85*93*91*4/7 | 85.0 | 93.0 | 4.0 | 91.0 | 7.0 |

| STW-90*98*96*4/7 | 90.0 | 98.0 | 4.0 | 96.0 | 7.0 |

| STW-95*103*101*4/7 | 95.0 | 103.0 | 4.0 | 101.0 | 7.0 |

| STW-100*108*106*4/7 | 100.0 | 108.0 | 4.0 | 106.0 | 7.0 |

| STW-110*122*119*5.5/10 | 110.0 | 122.0 | 5.5 | 119.0 | 10.0 |

| STW-115*127*124*5.5/10 | 115.0 | 127.0 | 5.5 | 124.0 | 10.0 |

| STW-120*132*129*5.5/10 | 120.0 | 132.0 | 5.5 | 129.0 | 10.0 |

| STW-125*137*134*5.5/10 | 125.0 | 137.0 | 5.5 | 134.0 | 10.0 |

| STW-130*142*139*5.5/10 | 130.0 | 142.0 | 5.5 | 139.0 | 10.0 |

| STW-140*152*149*5.5/10 | 140.0 | 152.0 | 5.5 | 149.0 | 10.0 |

| STW-150*162*159*5.5/10 | 150.0 | 162.0 | 5.5 | 159.0 | 10.0 |

Material: TPU

Groove: ISO 6195 Type C

HW rod wipers have a double lip snap-in design with an internal-facing wiper lip that regulates the lubrication film on the rod. The internal lip wipes away any excess fluid film from the rod on the extending stroke and allows this excess fluid to return under the rod seal on the retracting stroke. Double acting wipers therefore improve the performance and extend the service life of rod sealing systems. HW wipers are available in metric and imperial sizes.

| Part No | (d) ±f7 | (D) ±H9 | (L) +0.25 | (D₂) +0.25 | (C) min |

|---|---|---|---|---|---|

| HW-12*18.6*3.8 | 12.0 | 18.6 | 3.8 | 15.0 | 3.5 |

| HW-14*20.6*3.8 | 14.0 | 20.6 | 3.8 | 17.0 | 3.5 |

| HW-14*22*5 | 14.0 | 22.0 | 5.0 | 18.0 | 3.5 |

| HW-16*24*5 | 16.0 | 24.0 | 5.0 | 20.0 | 3.5 |

| HW-18*34.6*3.8 | 18.0 | 24.6 | 3.8 | 21.0 | 3.5 |

| HW-18*26*5 | 18.0 | 26.0 | 5.0 | 22.0 | 3.5 |

| HW-20*26*4 | 20.0 | 26.0 | 4.0 | 22.5 | 3.5 |

| HW-20*28*5 | 20.0 | 28.0 | 5.0 | 24.0 | 3.5 |

| HW-22*28.6*3.8 | 22.0 | 28.6 | 3.8 | 25.0 | 3.5 |

| HW-22*30*5 | 22.0 | 30.0 | 5.0 | 26.0 | 3.5 |

| HW-25*31.6*3.8 | 25.0 | 31.6 | 3.8 | 28.0 | 3.5 |

| HW-25*33*5 | 25.0 | 33.0 | 5.0 | 29.0 | 3.5 |

| HW-28*36*5 | 28.0 | 36.0 | 5.0 | 32.0 | 3.5 |

| HW-30*38*5 | 30.0 | 38.0 | 5.0 | 33.0 | 3.5 |

| HW-30*38*6 | 30.0 | 38.0 | 6.0 | 34.0 | 3.5 |

| HW-32*40*5 | 32.0 | 40.0 | 5.0 | 35.0 | 3.5 |

| HW-32*40*6 | 32.0 | 40.0 | 6.0 | 36.0 | 3.5 |

| HW-35*43*6 | 35.0 | 43.0 | 6.0 | 39.0 | 3.5 |

| HW-36*44*5 | 36.0 | 44.0 | 5.0 | 39.0 | 3.5 |

| HW-36*44*6 | 36.0 | 44.0 | 6.0 | 40.0 | 3.5 |

| HW-40*48*5 | 40.0 | 48.0 | 5.0 | 43.0 | 3.5 |

| HW-40*48*6 | 40.0 | 48.0 | 6.0 | 44.0 | 3.5 |

| HW-45*53*5 | 45.0 | 53.0 | 5.0 | 48.0 | 3.5 |

| HW-45*53*6 | 45.0 | 53.0 | 6.0 | 49.0 | 3.5 |

| HW-50*58*5 | 50.0 | 58.0 | 5.0 | 53.0 | 3.5 |

| HW-50*58*6 | 50.0 | 58.0 | 6.0 | 54.0 | 3.5 |

| HW-55*63*6 | 55.0 | 63.0 | 6.0 | 59.0 | 3.5 |

| HW-56*64*6 | 56.0 | 64.0 | 6.0 | 60.0 | 3.5 |

| HW-56*66*6 | 56.0 | 66.0 | 6.0 | 59.0 | 3.5 |

| HW-60*68*6 | 60.0 | 68.0 | 6.0 | 64.0 | 3.5 |

| HW-60*70.6*5.3 | 60.0 | 70.6 | 5.3 | 63.0 | 3.5 |

| HW-63*71*6 | 63.0 | 71.0 | 6.0 | 67.0 | 3.5 |

| HW-63*73.6*5.3 | 63.0 | 73.6 | 5.3 | 66.0 | 3.5 |

| HW-65*73*6 | 65.0 | 73.0 | 6.0 | 69.0 | 3.5 |

| HW-67*75*6 | 67.0 | 75.0 | 6.0 | 71.0 | 3.5 |

| HW-70*80*7 | 70.0 | 80.0 | 7.0 | 75.0 | 3.5 |

| HW-75*85*7 | 75.0 | 85.0 | 7.0 | 80.0 | 3.5 |

| HW-80*90*7 | 80.0 | 90.0 | 7.0 | 85.0 | 3.5 |

| HW-85*95*7 | 85.0 | 95.0 | 7.0 | 90.0 | 3.5 |

| HW-90*100*6 | 90.0 | 100.0 | 6.0 | 93.0 | 3.5 |

| HW-90*100*7 | 90.0 | 100.0 | 7.0 | 95.0 | 3.5 |

| HW-95*105*7 | 95.0 | 105.0 | 7.0 | 100.0 | 3.5 |

| HW-98*108*7 | 98.0 | 108.0 | 7.0 | 103.0 | 3.5 |

| HW-100*110*7 | 100.0 | 110.0 | 7.0 | 105.0 | 3.5 |

| HW-105*115*7 | 105.0 | 115.0 | 7.0 | 110.0 | 3.5 |

| HW-110*125*8.5 | 110.0 | 125.0 | 8.5 | 114.0 | 3.5 |

| HW-112*122*7 | 112.0 | 122.0 | 7.0 | 117.0 | 3.5 |

| HW-125*138*8 | 125.0 | 138.0 | 8.0 | 132.0 | 4.5 |

| HW-140*153*8 | 140.0 | 153.0 | 8.0 | 147.0 | 4.5 |

| HW-140*155*8.5 | 140.0 | 155.0 | 8.5 | 144.0 | 4.5 |

| Part No | (d) ±f7 | (D) ±H9 | (L) +.015 | (D2) +.003 | (C) min |

|---|---|---|---|---|---|

| HW-0250U | 0.250 | 0.552 | 0.203 | 0.370 | 0.187 |

| HW-0500U | 0.500 | 0.802 | 0.203 | 0.620 | 0.187 |

| HW-0625U | 0.625 | 0.927 | 0.203 | 0.745 | 0.187 |

| HW-0750U | 0.750 | 1.052 | 0.203 | 0.870 | 0.187 |

| HW-0937U | 0.937 | 1.302 | 0.218 | 1.072 | 0.187 |

| HW-1000U | 1.000 | 1.365 | 0.218 | 1.135 | 0.187 |

| HW-1250U | 1.250 | 1.615 | 0.218 | 1.385 | 0.187 |

| HW-1375U | 1.375 | 1.740 | 0.218 | 1.510 | 0.187 |

| HW-1437U | 1.437 | 1.802 | 0.218 | 1.572 | 0.187 |

| HW-1500U | 1.500 | 1.865 | 0.218 | 1.635 | 0.187 |

| HW-1625U | 1.625 | 1.990 | 0.218 | 1.760 | 0.187 |

| HW-1750U | 1.750 | 2.115 | 0.218 | 1.885 | 0.187 |

| HW-1875U | 1.875 | 2.240 | 0.218 | 2.010 | 0.187 |

| HW-2000U | 2.000 | 2.365 | 0.218 | 2.135 | 0.187 |

| HW-2125U | 2.125 | 2.490 | 0.218 | 2.260 | 0.187 |

| HW-2250U | 2.250 | 2.745 | 0.281 | 2.385 | 0.250 |

| HW-2500U | 2.500 | 2.995 | 0.281 | 2.635 | 0.250 |

| HW-2625U | 2.625 | 3.120 | 0.281 | 2.760 | 0.250 |

| HW-3000U | 3.000 | 3.495 | 0.281 | 3.135 | 0.250 |

| HW-3250U | 3.250 | 3.745 | 0.281 | 3.385 | 0.250 |

| HW-3500U | 3.500 | 3.995 | 0.281 | 3.635 | 0.250 |

| HW-3750U | 3.750 | 4.245 | 0.281 | 3.885 | 0.250 |

| HW-4000U | 4.000 | 4.495 | 0.281 | 4.135 | 0.250 |

| HW-4250U | 4.250 | 4.745 | 0.281 | 4.385 | 0.250 |

| HW-4500U | 4.500 | 4.995 | 0.281 | 4.635 | 0.250 |

| HW-4750U | 4.750 | 5.245 | 0.281 | 4.885 | 0.250 |

| HW-5000U | 5.000 | 5.495 | 0.281 | 5.135 | 0.250 |

| HW-5125U | 5.125 | 5.620 | 0.281 | 5.260 | 0.250 |

| HW-5250U | 5.250 | 5.745 | 0.281 | 5.385 | 0.250 |

| HW-7000U | 7.000 | 7.495 | 0.281 | 7.135 | 0.250 |

| HW-8000U | 8.000 | 8.495 | 0.281 | 8.135 | 0.250 |

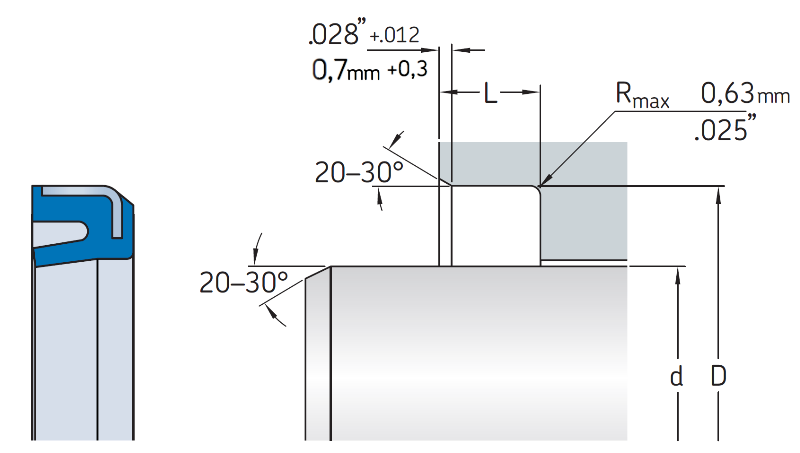

Material: TPU

Groove: ANSI B93.35:1978

AN/A9S rod wipers have a single lip snap-in design and a short square shoulder. AN/A9S wipers feature a slotted heel; vents on the inside edge prevent the wiper trapping pressure the wiper trapping pressure or being pushed out by pressure in the event the rod seal has become damaged or has exceeded its service life. Commonly found on American equipment, AN/A9S wipers are available in imperial sizes for housings in accordance to AN6231 and ANSI/B93.35M.

| Part No | (d) | (D) | (L) | (D₂) |

|---|---|---|---|---|

| AN-01U | 0.500 | 0.760 | 0.107 | 0.647 |

| AN-03U | 0.625 | 0.885 | 0.107 | 0.772 |

| AN-05U | 0.750 | 1.010 | 0.107 | 0.897 |

| AN-06U | 0.812 | 1.084 | 0.107 | 0.960 |

| AN-07U | 0.875 | 1.147 | 0.107 | 1.023 |

| AN-08U | 0.937 | 1.209 | 0.107 | 1.085 |

| AN-09U | 1.000 | 1.272 | 0.107 | 1.148 |

| AN-10U | 1.062 | 1.334 | 0.107 | 1.210 |

| AN-11U | 1.125 | 1.397 | 0.107 | 1.273 |

| AN-13U | 1.250 | 1.522 | 0.107 | 1.398 |

| AN-14U | 1.312 | 1.614 | 0.107 | 1.480 |

| AN-15U | 1.375 | 1.677 | 0.107 | 1.542 |

| AN-16U | 1.437 | 1.739 | 0.107 | 1.605 |

| AN-17U | 1.500 | 1.802 | 0.107 | 1.668 |

| AN-18U | 1.625 | 1.927 | 0.107 | 1.793 |

| AN-19U | 1.750 | 2.052 | 0.107 | 1.918 |

| AN-20U | 1.875 | 2.177 | 0.107 | 2.043 |

| AN-21U | 2.000 | 2.302 | 0.107 | 2.178 |

| AN-22U | 2.125 | 2.427 | 0.107 | 2.303 |

| AN-23U | 2.250 | 2.552 | 0.107 | 2.428 |

| AN-24U | 2.375 | 2.677 | 0.107 | 2.553 |

| AN-25U | 2.500 | 2.802 | 0.107 | 2.678 |

| AN-26U | 2.625 | 2.989 | 0.122 | 2.834 |

| AN-27U | 2.750 | 3.114 | 0.122 | 2.959 |

| AN-28U | 2.875 | 3.239 | 0.122 | 3.084 |

| AN-29U | 3.000 | 3.364 | 0.122 | 3.209 |

| AN-33U | 3.500 | 3.864 | 0.122 | 3.709 |

| AN-35U | 3.750 | 4.114 | 0.122 | 3.959 |

| AN-37U | 4.000 | 4.427 | 0.138 | 4.240 |

| AN-39U | 4.250 | 4.677 | 0.138 | 4.490 |

| AN-41U | 4.500 | 4.927 | 0.138 | 4.740 |

| AN-42U | 4.625 | 5.052 | 0.138 | 4.865 |

| AN-45U | 5.000 | 5.427 | 0.138 | 5.240 |

| AN-46U | 5.125 | 5.552 | 0.138 | 5.365 |

| AN-49U | 5.500 | 5.927 | 0.138 | 5.740 |

| AN-50U | 5.625 | 6.114 | 0.154 | 5.896 |

| AN-53U | 6.000 | 6.489 | 0.154 | 6.272 |

| AN-54U | 6.250 | 6.739 | 0.154 | 6.522 |

| AN-56U | 6.750 | 7.239 | 0.154 | 7.022 |

| AN-57U | 7.000 | 7.489 | 0.154 | 7.272 |

| AN-58U | 7.250 | 7.739 | 0.154 | 7.522 |

| AN-59U | 7.500 | 7.989 | 0.154 | 7.772 |

| AN-61U | 8.000 | 8.484 | 0.154 | 8.272 |

| AN-61.5U | 8.250 | 8.739 | 0.154 | 8.522 |

| AN-63U | 9.000 | 9.489 | 0.154 | 9.272 |

| AN-64U | 9.500 | 9.989 | 0.154 | 9.772 |

| AN-65U | 10.000 | 10.489 | 0.154 | 10.272 |

| AN-66U | 10.500 | 10.989 | 0.154 | 10.772 |

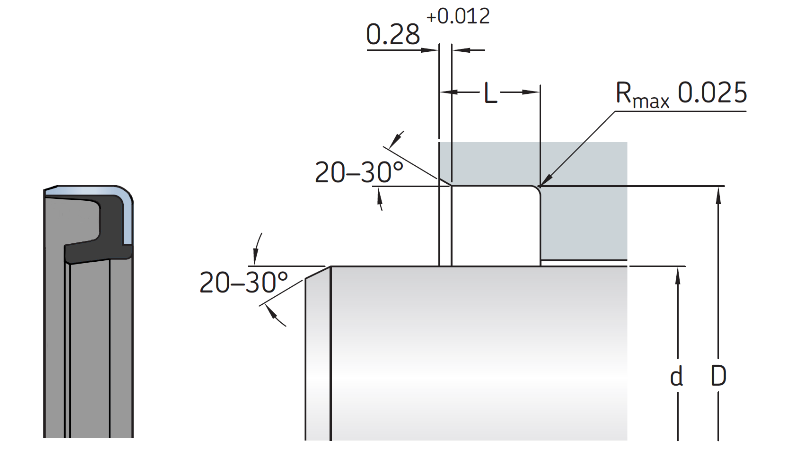

Material: TPU

Groove: ISO 6195 Type A

DSW are a D-style snap-in rod wiper and have a single lip design and radial double bump static sealing lips on the outside surface that maintains a positive sealing contact with the rod. DSW wipers feature a slotted heel; vents on the inside edge that prevent the wiper trapping pressure or being pushed out of the groove by pressure in the event the rod seal has become damaged or has exceeded its service life.

| Part No | (d) ±f7 | (D) +.006 | (L) +.004 | (D₂) +.010 |

|---|---|---|---|---|

| DSW-0312 | 0.312 | 0.560 | 0.124 | 0.475 |

| DSW-0375 | 0.375 | 0.622 | 0.124 | 0.535 |

| DSW-0437 | 0.437 | 0.685 | 0.124 | 0.600 |

| DSW-0500 | 0.500 | 0.747 | 0.124 | 0.660 |

| DSW-0562 | 0.562 | 0.810 | 0.124 | 0.725 |

| DSW-0625 | 0.625 | 0.872 | 0.124 | 0.785 |

| DSW-0687 | 0.687 | 0.935 | 0.124 | 0.850 |

| DSW-0750 | 0.750 | 1.122 | 0.187 | 0.995 |

| DSW-1000 | 1.000 | 1.372 | 0.187 | 1.245 |

| DSW-1062 | 1.062 | 1.435 | 0.187 | 1.310 |

| DSW-1125 | 1.125 | 1.497 | 0.187 | 1.370 |

| DSW-1250 | 1.250 | 1.622 | 0.187 | 1.495 |

| DSW-1312 | 1.312 | 1.685 | 0.187 | 1.560 |

| DSW-1375 | 1.375 | 1.747 | 0.187 | 1.620 |

| DSW-1500 | 1.500 | 1.872 | 0.187 | 1.745 |

| DSW-1625 | 1.625 | 1.997 | 0.187 | 1.870 |

| DSW-1750 | 1.750 | 2.122 | 0.187 | 1.995 |

| DSW-1875 | 1.875 | 2.247 | 0.187 | 2.120 |

| DSW-2000 | 2.000 | 2.497 | 0.249 | 2.327 |

| DSW-2125 | 2.125 | 2.622 | 0.249 | 2.452 |

| DSW-2250 | 2.250 | 2.747 | 0.249 | 2.577 |

| DSW-2375 | 2.375 | 2.872 | 0.249 | 2.702 |

| DSW-2500 | 2.500 | 2.997 | 0.249 | 2.827 |

| DSW-2625 | 2.625 | 3.122 | 0.249 | 2.952 |

| DSW-2750 | 2.750 | 3.247 | 0.249 | 3.077 |

| DSW-3000 | 3.000 | 3.497 | 0.249 | 3.327 |

| DSW-3125 | 3.125 | 3.622 | 0.249 | 3.452 |

| DSW-3250 | 3.250 | 3.747 | 0.249 | 3.577 |

| DSW-3375 | 3.375 | 3.872 | 0.249 | 3.702 |

| DSW-3500 | 3.500 | 3.997 | 0.249 | 3.827 |

| DSW-3625 | 3.625 | 4.122 | 0.249 | 3.952 |

| DSW-3750 | 3.750 | 4.247 | 0.249 | 4.077 |

| DSW-4000 | 4.000 | 4.497 | 0.249 | 4.327 |

| DSW-4250 | 4.250 | 4.747 | 0.249 | 4.577 |

| DSW-4500 | 4.500 | 5.247 | 0.374 | 4.993 |

| DSW-4750 | 4.750 | 5.497 | 0.374 | 5.243 |

| DSW-5000 | 5.000 | 5.747 | 0.374 | 5.493 |

| DSW-5500 | 5.500 | 6.247 | 0.374 | 5.993 |

| DSW-5750 | 5.750 | 6.497 | 0.374 | 6.243 |

| DSW-5875 | 5.875 | 6.622 | 0.374 | 6.368 |

| DSW-6000 | 6.000 | 6.747 | 0.374 | 6.493 |

| DSW-6500 | 6.500 | 7.247 | 0.374 | 6.993 |

| DSW-6750 | 6.750 | 7.497 | 0.374 | 7.243 |

| DSW-7000 | 7.000 | 7.747 | 0.374 | 7.493 |

| DSW-7250 | 7.250 | 7.997 | 0.374 | 7.743 |

| DSW-7500 | 7.500 | 8.247 | 0.374 | 7.993 |

| DSW-7750 | 7.750 | 8.497 | 0.374 | 8.243 |

| DSW-8000 | 8.000 | 8.747 | 0.374 | 8.493 |

| DSW-8250 | 8.250 | 8.997 | 0.374 | 8.743 |

| DSW-8750 | 8.750 | 9.497 | 0.374 | 9.243 |

| DSW-9000 | 9.000 | 9.747 | 0.374 | 9.493 |

| DSW-10000 | 10.000 | 10.997 | 0.499 | 10.659 |

| DSW-10250 | 10.250 | 11.247 | 0.499 | 10.909 |

| DSW-10500 | 10.500 | 11.497 | 0.499 | 11.159 |

| DSW-10750 | 10.750 | 11.747 | 0.499 | 11.409 |

| DSW-11000 | 11.000 | 11.997 | 0.499 | 11.659 |

| DSW-11500 | 11.500 | 14.497 | 0.499 | 12.159 |

| DSW-12000 | 12.000 | 12.997 | 0.499 | 12.659 |

| DSW-12500 | 12.500 | 13.497 | 0.499 | 13.159 |

Material: TPU/NBR

Groove: ISO 6195 Type D

DX are a snap-in rod wiper that fit D-style rod wiper grooves. DX wipers have a patented profile with a single lip design and are vented on the inside edge. These profiles incorporate a rubber o’ring that maintains a robust static sealing contact in the groove. The o’ring also serves as an energiser and provides robust and long term preload on the dynamic wiper lip. In case of radial misalignment, the entire TPU wiper ring follows the eccentric movement as the relatively soft and flexible rubber o’ring energiser deforms to compensate.

When the wiper lip encounters resistance from stout contaminants adhered to the rod such as tree sap, dried mud or frozen rain, the profile twists as the rod retracts and increases the preload on the dynamic wiper lip. Therefore, DX profiles include the functionality of press-fit wipers as with the convenience of snap-in wipers. DX wipers are available in imperial sizes for D-style grooves.

| Part No | (d) ±f7 | (D) +.006 | (L) +.004 | (D₂) +.010 |

|---|---|---|---|---|

| DX-0750 | 0.750 | 1.122 | 0.187 | 0.995 |

| DX-1000 | 1.000 | 1.372 | 0.187 | 1.245 |

| DX-1125 | 1.125 | 1.497 | 0.187 | 1.370 |

| DX-1250 | 1.250 | 1.622 | 0.187 | 1.495 |

| DX-1375 | 1.375 | 1.747 | 0.187 | 1.620 |

| DX-1500 | 1.500 | 1.872 | 0.187 | 1.745 |

| DX-1625 | 1.625 | 1.997 | 0.187 | 1.870 |

| DX-1750 | 1.750 | 2.122 | 0.187 | 1.995 |

| DX-2000 | 2.000 | 2.497 | 0.249 | 2.327 |

| DX-2250 | 2.250 | 2.747 | 0.249 | 2.577 |

| DX-2500 | 2.500 | 2.997 | 0.249 | 2.827 |

| DX-2750 | 2.750 | 3.247 | 0.249 | 3.077 |

| DX-3000 | 3.000 | 3.497 | 0.249 | 3.327 |

| DX-3125 | 3.125 | 3.622 | 0.249 | 3.452 |

| DX-3250 | 3.250 | 3.747 | 0.249 | 3.577 |

| DX-3375 | 3.375 | 3.872 | 0.249 | 3.702 |

| DX-3500 | 3.500 | 3.997 | 0.249 | 3.827 |

| DX-3750 | 3.750 | 4.247 | 0.249 | 4.077 |

| DX-4000 | 4.000 | 4.497 | 0.249 | 4.327 |

| DX-4250 | 4.250 | 4.747 | 0.249 | 4.577 |

| DX-4500 | 4.500 | 5.247 | 0.374 | 4.993 |

| DX-4625 | 4.625 | 5.372 | 0.374 | 5.118 |

| DX-4750 | 4.750 | 5.497 | 0.374 | 5.243 |

| DX-5000 | 5.000 | 5.747 | 0.374 | 5.493 |

| DX-5500 | 5.500 | 6.247 | 0.374 | 5.993 |

| DX-5750 | 5.750 | 6.497 | 0.374 | 6.243 |

| DX-6000 | 6.000 | 6.747 | 0.374 | 6.493 |

| DX-6500 | 6.500 | 7.247 | 0.374 | 6.993 |

| DX-7000 | 7.000 | 7.747 | 0.374 | 7.493 |

| DX-7250 | 7.250 | 7.997 | 0.374 | 7.743 |

| DX-8000 | 8.000 | 8.747 | 0.374 | 8.493 |

| DX-8500 | 8.500 | 9.247 | 0.374 | 8.993 |

| DX-9000 | 9.000 | 9.747 | 0.374 | 9.493 |

Material: TPU/Metal

Groove: ISO 6195 Type B

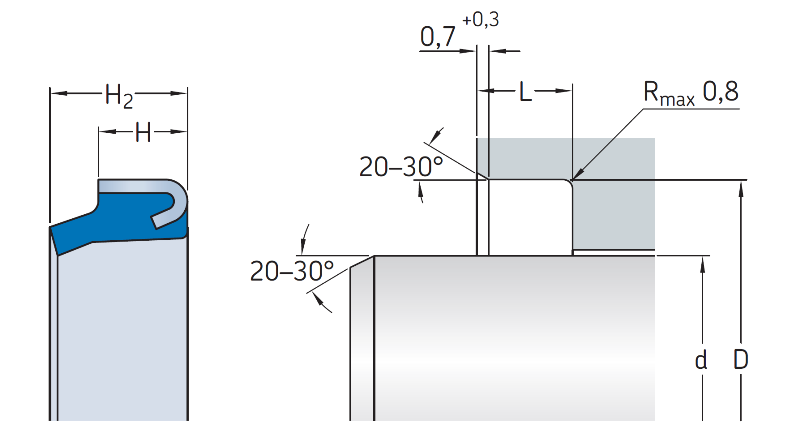

PA rod wipers are a heavy duty single lip press-fit design with a wiping lip that protrudes from the shoulder. This design allows for small radial cross sections and reduces the risk of contaminants adhering to the wiper lip. PA profiles are suitable for heavy duty off-highway applications and are available in metric sizes.

| Part No | (d) ±f7 | (D) ±H8 | (L) ±0.25 | (H) | (H₂) |

|---|---|---|---|---|---|

| PA-12*20*4/6 | 12.0 | 20.0 | 4.5 | 4.0 | 6.0 |

| PA-15*25*5/8 | 15.0 | 25.0 | 5.5 | 5.0 | 8.0 |

| PA-16*22*3/4 | 16.0 | 22.0 | 3.5 | 3.0 | 4.0 |

| PA-16*26*5/8 | 16.0 | 26.0 | 5.5 | 5.0 | 8.0 |

| PA-18*28*5/7 | 18.0 | 28.0 | 5.5 | 5.0 | 7.0 |

| PA-18*28*7/10 | 18.0 | 28.0 | 7.5 | 7.0 | 10.0 |

| PA-20*28*3.5/5 | 20.0 | 28.0 | 4.0 | 3.5 | 5.0 |

| PA-20*30*4/6 | 20.0 | 30.0 | 4.5 | 4.0 | 6.0 |

| PA-20*30*7/10 | 20.0 | 30.0 | 7.5 | 7.0 | 10.0 |

| PA-22*32*7/10 | 22.0 | 32.0 | 7.0 | 10.0 | |

| PA-25*35*5/8 | 25.0 | 35.0 | 5.5 | 5.0 | 8.0 |

| PA-25*35*7/10 | 25.0 | 35.0 | 7.5 | 7.0 | 10.0 |

| PA-25*37*6/9 | 25.0 | 37.0 | 6.5 | 6.0 | 9.0 |

| PA-28*38*5/8 | 28.0 | 38.0 | 5.5 | 5.0 | 8.0 |

| PA-28*38*7/10 | 28.0 | 38.0 | 7.5 | 7.0 | 10.0 |

| PA-28*40*7/10 | 28.0 | 40.0 | 7.5 | 7.0 | 10.0 |

| PA-30*40*5/8 | 30.0 | 40.0 | 5.5 | 5.0 | 8.0 |

| PA-30*40*7/10 | 30.0 | 40.0 | 7.5 | 7.0 | 10.0 |

| PA-30*42*6/9 | 30.0 | 42.0 | 6.5 | 6.0 | 9.0 |

| PA-32*42*7/10 | 32.0 | 42.0 | 7.5 | 7.0 | 10.0 |

| PA-32*45*4/8 | 32.0 | 45.0 | 4.5 | 4.0 | 8.0 |

| PA-32*45*7/10 | 32.0 | 45.0 | 7.5 | 7.0 | 10.0 |

| PA-35*45*7/10 | 35.0 | 45.0 | 7.5 | 7.0 | 10.0 |

| PA-36*45*7/10 | 36.0 | 45.0 | 7.5 | 7.0 | 10.0 |

| PA-36*46*7/10 | 36.0 | 46.0 | 7.5 | 7.0 | 10.0 |

| PA-38*48*7/10 | 38.0 | 48.0 | 7.5 | 7.0 | 10.0 |

| PA-40*50*5/8 | 40.0 | 50.0 | 5.5 | 5.0 | 8.0 |

| PA-40*50*7/10 | 40.0 | 50.0 | 7.5 | 7.0 | 10.0 |

| PA-42*52*7/10 | 42.0 | 52.0 | 7.5 | 7.0 | 10.0 |

| PA-45*55*5/8 | 45.0 | 55.0 | 5.5 | 5.0 | 8.0 |

| PA-45*55*7/10 | 45.0 | 55.0 | 7.5 | 7.0 | 10.0 |

| PA-45*60*7/10 | 45.0 | 60.0 | 7.5 | 7.0 | 10.0 |

| PA-50*56*5/8 | 50.0 | 56.0 | 5.5 | 5.0 | 8.0 |

| PA-50*60*5/8 | 50.0 | 60.0 | 5.5 | 5.0 | 8.0 |

| PA-50*60*7/10 | 50.0 | 60.0 | 7.5 | 7.0 | 10.0 |

| PA-50*65*7/10 | 50.0 | 65.0 | 7.5 | 7.0 | 10.0 |

| PA-55*63*7/10 | 55.0 | 63.0 | 7.5 | 7.0 | 10.0 |

| PA-55*65*5/8 | 55.0 | 65.0 | 5.5 | 5.0 | 8.0 |

| PA-55*65*7/10 | 55.0 | 65.0 | 7.5 | 7.0 | 10.0 |

| PA-55*70*7/10 | 55.0 | 70.0 | 7.5 | 7.0 | 10.0 |

| PA-56*66*7/10 | 56.0 | 66.0 | 7.5 | 7.0 | 10.0 |

| PA-60*70*7/10 | 60.0 | 70.0 | 7.5 | 7.0 | 10.0 |

| PA-60*74*8/11 | 60.0 | 74.0 | 8.5 | 8.0 | 11.0 |

| PA-63*73*7/10 | 63.0 | 73.0 | 7.5 | 7.0 | 10.0 |

| PA-63*75*7/10 | 63.0 | 75.0 | 7.5 | 7.0 | 10.0 |

| PA-63*78*7/10 | 63.0 | 78.0 | 7.5 | 7.0 | 10.0 |

| PA-65*75*7/10 | 65.0 | 75.0 | 7.5 | 7.0 | 10.0 |

| PA-65*79*8/11 | 65.0 | 79.0 | 8.5 | 8.0 | 11.0 |

| PA-70*80*7/10 | 70.0 | 80.0 | 7.5 | 7.0 | 10.0 |

| PA-70*84*8/11 | 70.0 | 84.0 | 8.5 | 8.0 | 11.0 |

| PA-75*83*7/10 | 75.0 | 83.0 | 7.5 | 7.0 | 10.0 |

| PA-75*85*7/10 | 75.0 | 85.0 | 7.5 | 7.0 | 10.0 |

| PA-75*89*8/11 | 75.0 | 89.0 | 8.5 | 8.0 | 11.0 |

| PA-80*88*7/10 | 80.0 | 88.0 | 7.5 | 7.0 | 10.0 |

| PA-80*90*7/10 | 80.0 | 90.0 | 7.5 | 7.0 | 10.0 |

| PA-80*94*8/11 | 80.0 | 94.0 | 8.5 | 8.0 | 11.0 |

| PA-85*95*7/10 | 85.0 | 95.0 | 7.5 | 7.0 | 10.0 |

| PA-90*100*7/10 | 90.0 | 100.0 | 7.5 | 7.0 | 10.0 |

| PA-90*104*8/11 | 90.0 | 104.0 | 8.5 | 8.0 | 11.0 |

| PA-95*105*7/10 | 95.0 | 105.0 | 7.5 | 7.0 | 10.0 |

| PA-100*110*7/10 | 100.0 | 110.0 | 7.5 | 7.0 | 10.0 |

| PA-105*115*7/10 | 105.0 | 115.0 | 7.5 | 7.0 | 10.0 |

| PA-110*120*7/10 | 110.0 | 120.0 | 7.5 | 7.0 | 10.0 |

| PA-110*126*9/12 | 110.0 | 126.0 | 9.5 | 9.0 | 12.0 |

| PA-115*125*7/10 | 115.0 | 125.0 | 7.5 | 7.0 | 10.0 |

| PA-120*130*7/10 | 120.0 | 130.0 | 7.5 | 7.0 | 10.0 |

| PA-120*136*9/12 | 120.0 | 136.0 | 9.5 | 9.0 | 12.0 |

| PA-125*140*9/12 | 125.0 | 140.0 | 9.5 | 9.0 | 12.0 |

| PA-130*145*9/12 | 130.0 | 145.0 | 9.5 | 9.0 | 12.0 |

| PA-135*150*9/12 | 135.0 | 150.0 | 9.5 | 9.0 | 12.0 |

| PA-140*155*9/12 | 140.0 | 155.0 | 9.5 | 9.0 | 12.0 |

| PA-150*165*9/12 | 150.0 | 165.0 | 9.5 | 9.0 | 12.0 |

| PA-150*170*10/14 | 150.0 | 170.0 | 10.5 | 10.0 | 14.0 |

| PA-160*175*9/12 | 160.0 | 175.0 | 9.5 | 9.0 | 12.0 |

| PA-160*180*10/14 | 160.0 | 180.0 | 10.5 | 10.0 | 14.0 |

| PA-180*195*9/12 | 180.0 | 195.0 | 9.5 | 9.0 | 12.0 |

| PA-180*195*10/14 | 180.0 | 195.0 | 10.5 | 10.0 | 14.0 |

| PA-200*225*12/17 | 200.0 | 225.0 | 12.5 | 12.0 | 17.0 |

Material: NBR/Metal

Groove: ISO 6195 Type B

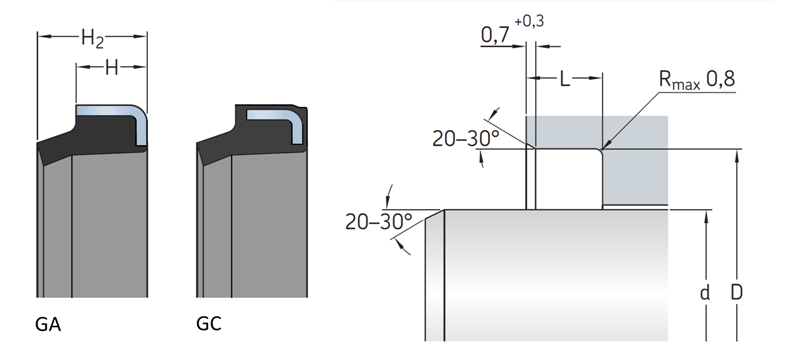

GA and GC rod wipers are medium to heavy duty single lip press-fit design with a rubber wiping lip that protrudes from the shoulder. This design allows small radial cross sections and reduces the risk of contaminants adhering to the wiper lip. GC wipers have a design where mating surfaces are completely covered in rubber and are ideal in situations where electrolysis between two mating metal parts can cause corrosion.

| Part No | (d) ±f7 | (D) ±H8 | (L) ±0.25 | (H) | (H₂) |

|---|---|---|---|---|---|

| GA-10*16*3/4.5 | 10.0 | 16.0 | 3.5 | 3.0 | 4.5 |

| GA-10*20*5/8 | 10.0 | 20.0 | 5.5 | 5.0 | 8.0 |

| GA-12*20*4/6 | 12.0 | 20.0 | 4.5 | 4.0 | 6.0 |

| GA-12*22*5/8 | 12.0 | 22.0 | 5.5 | 5.0 | 8.0 |

| GA-14*20*3.5/5 | 14.0 | 20.0 | 4.0 | 3.5 | 5.0 |

| GA-14*22*3/4 | 14.0 | 22.0 | 3.5 | 3.0 | 4.0 |

| GA-15*25*5/8 | 15.0 | 25.0 | 5.5 | 5.0 | 8.0 |

| GA-16*22*3/4 | 16.0 | 22.0 | 3.5 | 3.0 | 4.0 |

| GA-16*26*5/8 | 16.0 | 26.0 | 5.5 | 5.0 | 8.0 |

| GA-18*28*7/10 | 18.0 | 28.0 | 7.5 | 7.0 | 10.0 |

| GA-18*35*5/8 | 18.0 | 35.0 | 5.5 | 5.0 | 8.0 |

| GA-20*28*3/5 | 20.0 | 280 | 3.5 | 3.0 | 5.0 |

| GA-20*28*3.5/5 | 20.0 | 28.0 | 4.0 | 3.5 | 5.0 |

| GA-20*28*5/8 | 20.0 | 28.0 | 5.5 | 5.0 | 8.0 |

| GA-20*30*4/6 | 20.0 | 30.0 | 4.5 | 4.0 | 6.0 |

| GA-20*30*7/10 | 20.0 | 30.0 | 7.5 | 7.0 | 10.0 |

| GA-20*35*7/10 | 20.0 | 35.0 | 7.5 | 7.0 | 10.0 |

| GA-22*28*5/8 | 22.0 | 28.0 | 5.5 | 5.0 | 8.0 |

| GA-22*32*5/8 | 22.0 | 32.0 | 5.5 | 5.0 | 8.0 |

| GA-22*32*7/10 | 22.0 | 32.0 | 7.5 | 7.0 | 10.0 |

| GA-22*35*5/8 | 22.0 | 35.0 | 5.5 | 5.0 | 8.0 |

| GA-24*32*5/8 | 24.0 | 32.0 | 5.5 | 5.0 | 8.0 |

| GA-25*31*5/7 | 25.0 | 31.0 | 5.5 | 5.0 | 7.0 |

| GA-25*35*5/8 | 25.0 | 35.0 | 5.5 | 5.0 | 8.0 |

| GA-25*35*7/10 | 25.0 | 35.0 | 7.5 | 7.0 | 10.0 |

| GA-28*38*5/8 | 28.0 | 38.0 | 5.5 | 5.0 | 8.0 |

| GA-28*38*7/10 | 28.0 | 38.0 | 7.5 | 7.0 | 10.0 |

| GA-28*40*7/10 | 28.0 | 40.0 | 7.5 | 7.0 | 10.0 |

| GA-30*40*5/8 | 30.0 | 40.0 | 5.5 | 5.0 | 8.0 |

| GA-30*40*7/10 | 30.0 | 40.0 | 7.5 | 7.0 | 10.0 |

| GA-32*42*7/10 | 32.0 | 42.0 | 7.5 | 7.0 | 10.0 |

| GA-32*45*5/8 | 32.0 | 45.0 | 5.5 | 5.0 | 8.0 |

| GA-32*45*7/10 | 32.0 | 45.0 | 7.5 | 7.0 | 10.0 |

| GA-35*41*5/7 | 35.0 | 41.0 | 5.5 | 5.0 | 7.0 |

| GA-35*45*7/10 | 35.0 | 45.0 | 7.5 | 7.0 | 10.0 |

| GA-36*45*5/7 | 36.0 | 45.0 | 5.5 | 5.0 | 7.0 |

| GA-35*45*7/10 | 35.0 | 45.0 | 7.5 | 7.0 | 10.0 |

| GA-36*46*7/10 | 36.0 | 46.0 | 7.5 | 7.0 | 10.0 |

| GA-40*50*5/8 | 40.0 | 50.0 | 5.5 | 5.0 | 8.0 |

| GA-40*50*7/10 | 40.0 | 50.0 | 7.5 | 7.0 | 10.0 |

| GA-42*52*7/10 | 42.0 | 52.0 | 7.5 | 7.0 | 10.0 |

| GA-45*55*7/10 | 45.0 | 55.0 | 7.5 | 7.0 | 10.0 |

| GA-45*60*7/10 | 45.0 | 60.0 | 7.5 | 7.0 | 10.0 |

| GA-48*60*7/10 | 48.0 | 60.0 | 7.5 | 7.0 | 10.0 |

| GA-50*56*5/7 | 50.0 | 56.0 | 5.5 | 5.0 | 7.0 |

| GA-50*60*7/10 | 50.0 | 60.0 | 7.5 | 7.0 | 10.0 |

| GA-50*65*5/8 | 50.0 | 65.0 | 5.5 | 5.0 | 8.0 |

| GA-52*62*7/10 | 52.0 | 62.0 | 7.5 | 7.0 | 10.0 |

| GA-55*63*7/10 | 55.0 | 63.0 | 7.5 | 7.0 | 10.0 |

| GA-55*65*7/10 | 55.0 | 65.0 | 7.5 | 7.0 | 10.0 |

| GA-56*65*7/10 | 56.0 | 65.0 | 7.5 | 7.0 | 10.0 |

| GA-56*66*7/10 | 56.0 | 66.0 | 7.5 | 7.0 | 10.0 |

| GA-60*70*7/10 | 60.0 | 70.0 | 7.5 | 7.0 | 10.0 |

| GA-63*73*7/10 | 63.0 | 73.0 | 7.5 | 7.0 | 10.0 |

| GA-63*75*7/10 | 63.0 | 75.0 | 7.5 | 7.0 | 10.0 |

| GA-65*75*7/10 | 65.0 | 75.0 | 7.5 | 7.0 | 10.0 |

| GA-70*80*7/10 | 70.0 | 80.0 | 7.5 | 7.0 | 10.0 |

| GA-75*85*7/10 | 75.0 | 85.0 | 7.5 | 7.0 | 10.0 |

| GA-80*88*7/10 | 80.0 | 88.0 | 7.5 | 7.0 | 10.0 |

| GA-80*90*7/10 | 80.0 | 90.0 | 7.5 | 7.0 | 10.0 |

| GA-85*95*7/10 | 85.0 | 95.0 | 7.5 | 7.0 | 10.0 |

| GA-90*100*7/10 | 90.0 | 100.0 | 7.5 | 7.0 | 10.0 |

| GA-95*105*7/10 | 95.0 | 105.0 | 7.5 | 7.0 | 10.0 |

| GA-100*110*7/10 | 100.0 | 110.0 | 7.5 | 7.0 | 10.0 |

| GA-110*120*7/10 | 110.0 | 120.0 | 7.5 | 7.0 | 10.0 |

| GA-115*125*7/10 | 115.0 | 125.0 | 7.5 | 7.0 | 10.0 |

| GA-120*130*7/10 | 120.0 | 130.0 | 7.5 | 7.0 | 10.0 |

| GA-125*140*9/12 | 125.0 | 140.0 | 9.5 | 9.0 | 12.0 |

| GA-130*145*9/12 | 130.0 | 145.0 | 9.5 | 9.0 | 12.0 |

| GA-140*155*9/12 | 140.0 | 155.0 | 9.5 | 9.0 | 12.0 |

| GA-160*175*9/12 | 160.0 | 175.0 | 9.5 | 9.0 | 12.0 |

| GA-170*185*10/14 | 170.0 | 185.0 | 10.5 | 10.0 | 14.0 |

| GA-180*195*10/14 | 180.0 | 195.0 | 10.5 | 10.0 | 14.0 |

| GA-200*220*12/16 | 200.0 | 220.0 | 12.5 | 12.0 | 16.0 |

| Part No | (d) ±f7 | (D) ±H8 | (L) ±0.25 | (H) | (H₂) |

|---|---|---|---|---|---|

| GC-6*13*3/4.5 | 6.0 | 13.0 | 3.5 | 3.0 | 4.5 |

| GC-6*13*3.5/4.5 | 6.0 | 13.0 | 4.0 | 3.5 | 4.5 |

| GC-8*14*3.5/5 | 8.0 | 14.0 | 4.0 | 3.5 | 5.0 |

| GC-10*16*3.5/5 | 10.0 | 16.0 | 4.0 | 3.5 | 5.0 |

| GC-10*20*5/8 | 10.0 | 20.0 | 5.5 | 5.0 | 8.0 |

| GC-12*18*3.5/5 | 12.0 | 18.0 | 4.0 | 3.5 | 5.0 |

| GC-12*22*5/8 | 12.0 | 22.0 | 5.5 | 5.0 | 8.0 |

| GC-14*20*3.5/5 | 14.0 | 20.0 | 4.0 | 3.5 | 5.0 |

| GC-15*21*3.5/5 | 15.0 | 21.0 | 4.0 | 3.5 | 5.0 |

| GC-15*25*5/8 | 15.0 | 25.0 | 5.5 | 5.0 | 8.0 |

| GC-16*22*3/5 | 16.0 | 22.0 | 3.5 | 3.0 | 5.0 |

| GC-16*22*3.5/5 | 16.0 | 22.0 | 4.0 | 3.5 | 5.0 |

| GC-16*26*5/8 | 16.0 | 26.0 | 5.5 | 5.0 | 8.0 |

| GC-18*24*4/7 | 18.0 | 24.0 | 4.5 | 4.0 | 7.0 |

| GC-18*28*5/7 | 18.0 | 28.0 | 5.5 | 5.0 | 7.0 |

| GC-18*28*7/10 | 18.0 | 28.0 | 7.5 | 7.0 | 10.0 |

| GC-20*30*5/7 | 20.0 | 30.0 | 5.5 | 5.0 | 7.0 |

| GC-20*30*7/10 | 20.0 | 30.0 | 7.5 | 7.0 | 10.0 |

| GC-22*32*5/7 | 22.0 | 32.0 | 5.5 | 5.0 | 7.0 |

| GC-22*32*7/10 | 22.0 | 32.0 | 7.5 | 7.0 | 10.0 |

| GC-24*35*5/8 | 24.0 | 35.0 | 5.5 | 5.0 | 8.0 |

| GC-25*35*5/7 | 25.0 | 35.0 | 5.5 | 5.0 | 7.0 |

| GC-25*35*7/10 | 25.0 | 35.0 | 7.5 | 7.0 | 10.0 |

| GC-26*35*7/10 | 26.0 | 35.0 | 7.5 | 7.0 | 10.0 |

| GC-28*38*5/7 | 28.0 | 38.0 | 5.5 | 5.0 | 7.0 |

| GC-28*40*7/10 | 28.0 | 40.0 | 7.5 | 7.0 | 10.0 |

| GC-30*40*5/7 | 30.0 | 40.0 | 5.5 | 5.0 | 7.0 |

| GC-30*40*7/10 | 30.0 | 40.0 | 7.5 | 7.0 | 10.0 |

| GC-32*42*5/7 | 32.0 | 42.0 | 5.5 | 5.0 | 7.0 |

| GC-32*45*7/10 | 32.0 | 45.0 | 7.5 | 7.0 | 10.0 |

| GC-35*45*7/10 | 35.0 | 45.0 | 7.5 | 7.0 | 10.0 |

| GC-36*45*7/10 | 36.0 | 45.0 | 7.5 | 7.0 | 10.0 |

| GC-36*46*5/7 | 36.0 | 46.0 | 5.5 | 5.0 | 7.0 |

| GC-38*48*7/10 | 38.0 | 48.0 | 7.5 | 7.0 | 10.0 |

| GC-40*50*5/8 | 40.0 | 50.0 | 5.5 | 5.0 | 8.0 |

| GC-40*50*7/10 | 40.0 | 50.0 | 7.5 | 7.0 | 10.0 |

| GC-42*52*7/10 | 42.0 | 52.0 | 7.5 | 7.0 | 10.0 |

| GC-45*55*5/7 | 45.0 | 55.0 | 5.5 | 5.0 | 7.0 |

| GC-45*55*7/10 | 45.0 | 55.0 | 7.5 | 7.0 | 10.0 |

| GC-48*60*7/10 | 48.0 | 60.0 | 7.5 | 7.0 | 10.0 |

| GC-50*60*5/7 | 50.0 | 60.0 | 5.5 | 5.0 | 7.0 |

| GC-50*60*7/10 | 50.0 | 60.0 | 7.5 | 7.0 | 10.0 |

| GC-52*62*7/10 | 52.0 | 62.0 | 7.5 | 7.0 | 10.0 |

| GC-55*65*5/7 | 55.0 | 65.0 | 5.5 | 5.0 | 7.0 |

| GC-55*65*7/10 | 55.0 | 65.0 | 7.5 | 7.0 | 10.0 |

| GC-60*70*5/7 | 60.0 | 70.0 | 5.5 | 5.0 | 7.0 |

| GC-60*70*7/10 | 60.0 | 70.0 | 7.5 | 7.0 | 10.0 |

| GC-65*75*5/7 | 65.0 | 75.0 | 5.5 | 5.0 | 7.0 |

| GC-65*75*7/10 | 65.0 | 75.0 | 7.5 | 7.0 | 10.0 |

| GC-70*80*5/7 | 70.0 | 80.0 | 5.5 | 5.0 | 7.0 |

| GC-70*80*7/10 | 70.0 | 80.0 | 7.5 | 7.0 | 10.0 |

| GC-75*83*7/10 | 75.0 | 83.0 | 7.5 | 7.0 | 10.0 |

| GC-75*85*7/10 | 75.0 | 85.0 | 7.5 | 7.0 | 10.0 |

| GC-80*88*7/10 | 80.0 | 88.0 | 7.5 | 7.0 | 10.0 |

| GC-80*90*7/10 | 80.0 | 90.0 | 7.5 | 7.0 | 10.0 |

| GC-85*95*7/10 | 85.0 | 95.0 | 7.5 | 7.0 | 10.0 |

| GC-90*100*7/10 | 90.0 | 100.0 | 7.5 | 7.0 | 10.0 |

| GC-95*105*7/10 | 95.0 | 105.0 | 7.5 | 7.0 | 10.0 |

| GC-100*110*7/10 | 100.0 | 110.0 | 7.5 | 7.0 | 10.0 |

| GC-100*120*7/10 | 100.0 | 120.0 | 7.5 | 7.0 | 10.0 |

| GC-105*115*7/10 | 105.0 | 115.0 | 7.5 | 7.0 | 10.0 |

| GC-110*120*7/10 | 110.0 | 120.0 | 7.5 | 7.0 | 10.0 |

| GC-115*125*7/10 | 115.0 | 125.0 | 7.5 | 7.0 | 10.0 |

| GC-120*130*7/10 | 120.0 | 130.0 | 7.5 | 7.0 | 10.0 |

| GC-125*140*9/12 | 125.0 | 140.0 | 9.5 | 9.0 | 12.0 |

| GC-130*145*9*12 | 130.0 | 145.0 | 9.5 | 9.0 | 12.0 |

| GC-140*155*9/12 | 140.0 | 155.0 | 9.5 | 9.0 | 12.0 |

| GC-150*165*9/12 | 150.0 | 165.0 | 9.5 | 9.0 | 12.0 |

| GC-160*175*9/12 | 160.0 | 175.0 | 9.5 | 9.0 | 12.0 |

| GC-170*185*10/14 | 170.0 | 185.0 | 10.5 | 10.0 | 14.0 |

| GC-180*195*10/14 | 180.0 | 195.0 | 10.5 | 10.0 | 14.0 |

| GC-200*220*12/16 | 200.0 | 220.0 | 12.5 | 12.0 | 16.0 |

| GC-220*240*12/16 | 220.0 | 240.0 | 12.5 | 12.0 | 16.0 |

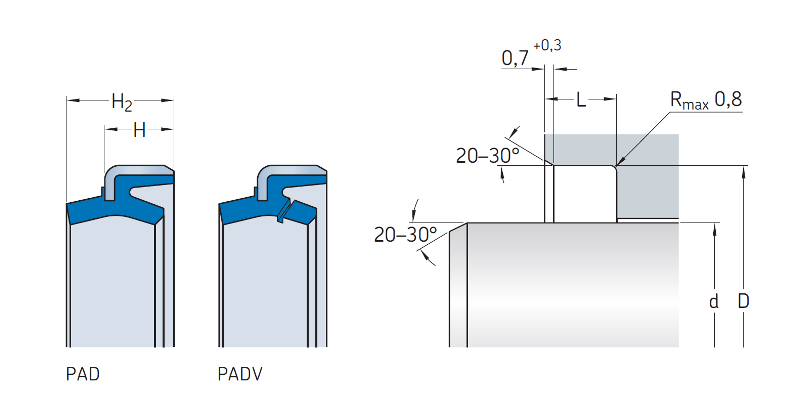

Material: TPU/METAL

PAD rod wipers are a heavy duty double lip press-fit design. The internal-facing wiper lip wipes excess fluid film from the rod on the extending stroke and allows this excess fluid to return under the rod seal on the retracting stroke. Double acting wipers therefore extend the service life of rod sealing systems. PAD profiles are also available with a vent in the internal lip (designation PADV; available upon request). The vent prevents pressure build up on the internal-facing lip. PAD and PADV wipers are available in metric sizes.

| Part No | (d) ±f7 | (D) ±H8 | (L) ±0.25 | (H) | (H₂) |

|---|---|---|---|---|---|

| PAD-30*42*6/9 | 30.0 | 42.0 | 6.5 | 6.0 | 9.0 |

| PAD-35*47*7/10 | 35.0 | 47.0 | 7.5 | 7.0 | 10.0 |

| PAD-40*52*7/10 | 40.0 | 52.0 | 7.5 | 7.0 | 10.0 |

| PAD-45*57*7/10 | 45.0 | 57.0 | 7.5 | 7.0 | 10.0 |

| PAD-50*62*7/10 | 50.0 | 62.0 | 7.5 | 7.0 | 10.0 |

| PAD-55*69*8/11 | 55.0 | 69.0 | 8.5 | 8.0 | 11.0 |

| PAD-60*74*8/11 | 60.0 | 74.0 | 8.5 | 8.0 | 11.0 |

| PAD-65*79*8/11 | 65.0 | 79.0 | 8.5 | 8.0 | 11.0 |

| PAD-70*84*8/11 | 70.0 | 84.0 | 8.5 | 8.0 | 11.0 |

| PAD-75*89*8/11 | 75.0 | 89.0 | 8.5 | 8.0 | 11.0 |

| PAD-80*84*8/11 | 80.0 | 94.0 | 8.5 | 8.0 | 11.0 |

| PAD-85*99*8/11 | 85.0 | 99.0 | 8.5 | 8.0 | 11.0 |

| PAD-90*104*8/11 | 90.0 | 104.0 | 8.5 | 8.0 | 11.0 |

| PAD-95*109*8/11 | 95.0 | 109.0 | 8.5 | 8.0 | 11.0 |

| PAD-100*114*8/11 | 100.0 | 114.0 | 8.5 | 8.0 | 11.0 |

| PAD-105*121*9/12 | 105.0 | 121.0 | 9.5 | 9.0 | 12.0 |

| PAD-110*126*9/12 | 110.0 | 126.0 | 9.5 | 9.0 | 12.0 |

| PAD-115*131*9/12 | 115.0 | 131.0 | 9.5 | 9.0 | 12.0 |

| PAD-120*136*9/12 | 120.0 | 136.0 | 9.5 | 9.0 | 12.0 |

Material: NBR/METAL

DKB rod wipers are a medium to heavy duty double lip press-fit design with a rubber lip. The internal-facing wiper lip wipes excess fluid film from the rod on the extending stroke and allows this excess fluid to return under the rod seal on the retracting stroke. Double acting wipers therefore extend the service life of rod sealing systems. DKB wipers are available in metric sizes.

| Part No | (d) ±f7 | (D) ±H8 | (L) ±0.25 | (H) | (H₂) |

|---|---|---|---|---|---|

| DKB-14*24*5/7 | 14.0 | 24.0 | 5.5 | 5.0 | 7.0 |

| DKB-16*26*5/7 | 16.0 | 26.0 | 5.5 | 5.0 | 7.0 |

| DKB-18*30*6/9 | 18.0 | 30.0 | 6.5 | 6.0 | 9.0 |

| DKB-19*26*5/7 | 19.0 | 26.0 | 5.5 | 5.0 | 7.0 |

| DKB-19*31*6/9 | 19.0 | 31.0 | 6.5 | 6.0 | 9.0 |

| DKB-19*32*6/9 | 19.0 | 32.0 | 6.5 | 6.0 | 9.0 |

| DKB-20*30*4/6 | 20.0 | 30.0 | 4.5 | 4.0 | 6.0 |

| DKB-20*32*6/9 | 20.0 | 32.0 | 6.5 | 6.0 | 9.0 |

| DKB-22*32*6/9 | 22.0 | 32.0 | 6.5 | 6.0 | 9.0 |

| DKB-22*34*6/9 | 22.0 | 34.0 | 6.5 | 6.0 | 9.0 |

| DKB-22.4*34.4*6/9 | 22.4 | 34.4 | 6.5 | 6.0 | 9.0 |

| DKB-25*37*6/9 | 25.0 | 37.0 | 6.5 | 6.0 | 9.0 |

| DKB-28*38*7/10 | 28.0 | 38.0 | 7.5 | 7.0 | 10.0 |

| DKB-28*40*6/9 | 28.0 | 40.0 | 6.5 | 6.0 | 9.0 |

| DKB-30*42*6/9 | 30.0 | 42.0 | 6.5 | 6.0 | 9.0 |

| DKB-30*45*6/9 | 30.0 | 45.0 | 6.5 | 6.0 | 9.0 |

| DKB-31.5*44*7/10 | 31.5 | 44.0 | 7.5 | 7.0 | 10.0 |

| DKB-32*44*7/10 | 32.00 | 44.0 | 7.5 | 7.0 | 10.0 |

| DKB-32*45*5/8 | 32.0 | 45.0 | 5.5 | 5.0 | 8.0 |

| DKB-32*45*7/10 | 32.0 | 45.0 | 7.5 | 7.0 | 10.0 |

| DKB-32*52*8/11 | 32.0 | 52.0 | 8.5 | 8.0 | 11.0 |

| DKB-35*47*7/10 | 35.0 | 47.0 | 7.5 | 7.0 | 10.0 |

| DKB-35.5*47.5*7/10 | 35.5 | 47.5 | 7.5 | 7.0 | 10.0 |

| DKB-36*48*7/10 | 36.0 | 48.0 | 7.5 | 7.0 | 10.0 |

| DKB-40*50*7/10 | 40.0 | 50.0 | 7.5 | 7.0 | 10.0 |

| DKB-40*52*7/10 | 40.0 | 52.0 | 7.5 | 7.0 | 10.0 |

| DKB-45*57*7/10 | 45.0 | 57.0 | 7.5 | 7.0 | 10.0 |

| DKB-50*62*7/10 | 50.0 | 62.0 | 7.5 | 7.0 | 10.0 |

| DKB-55*65*7/10 | 55.0 | 65.0 | 7.5 | 7.0 | 10.0 |

| DKB-55*69*8/11 | 55.0 | 69.0 | 8.5 | 8.0 | 11.0 |

| DKB-56*70*8/11 | 56.0 | 70.0 | 8.5 | 8.0 | 11.0 |

| DKB -60*74*8/11 | 60.0 | 74.0 | 8.5 | 8.0 | 11.0 |

| DKB-63*77*8/11 | 63.0 | 77.0 | 8.5 | 8.0 | 11.0 |

| DKB-65*79*8/11 | 65.0 | 79.0 | 8.5 | 8.0 | 11.0 |

| DKB-70*84*8/11 | 70.0 | 84.0 | 8.5 | 8.0 | 11.0 |

| DKB-75*89*8/11 | 75.0 | 89.0 | 8.5 | 8.0 | 11.0 |

| DKB-80*94*8/11 | 80.0 | 94.0 | 8.5 | 8.0 | 11.0 |

| DKB-85*99*8/11 | 85.0 | 99.0 | 8.5 | 8.0 | 11.0 |

| DKB -90*104*8/11 | 90.0 | 104.0 | 8.5 | 8.0 | 11.0 |

| DKB-95*109*8/11 | 95.0 | 109.0 | 8.5 | 8.0 | 11.0 |

| DKB-100*114*8/11 | 100.0 | 114.0 | 8.5 | 8.0 | 11.0 |

| DKB-105*121*9/12 | 105.0 | 121.0 | 9.5 | 9.0 | 12.0 |

| DKB-110*126*9/12 | 110.0 | 126.0 | 9.5 | 9.0 | 12.0 |

| DKB-112*128*9/12 | 112.0 | 128.0 | 9.5 | 9.0 | 12.0 |

| DKB-115*131*9/12 | 115.0 | 131.0 | 9.5 | 9.0 | 12.0 |

| DKB-120*136*9/12 | 120.0 | 136.0 | 9.5 | 9.0 | 12.0 |

| DKB-125*141*9/12 | 125.0 | 141.0 | 9.5 | 9.0 | 12.0 |

| DKB-130*146*9/12 | 130.0 | 146.0 | 9.5 | 9.0 | 12.0 |

| DKB-140*160*10/14 | 140.0 | 160.0 | 10.5 | 10.0 | 14.0 |

| DKB-145*165*10/14 | 145.0 | 165.0 | 10.5 | 10.0 | 14.0 |

| DKB-150*170*10/14 | 150.0 | 170.0 | 10.5 | 10.0 | 14.0 |

| DKB-155*175*10/14 | 155.0 | 175.0 | 10.5 | 10.0 | 14.0 |

| DKB-160*180*10/14 | 160.0 | 180.0 | 10.5 | 10.0 | 14.0 |

| DKB-170*190*10/14 | 170.0 | 190.0 | 10.5 | 10.0 | 14.0 |

| DKB-175*195*10/14 | 175.0 | 195.0 | 10.5 | 10.0 | 14.0 |

| DKB-180*205*12/17 | 180.0 | 205.0 | 12.5 | 12.0 | 17.0 |

| DKB-200*225*12/17 | 200.0 | 225.0 | 12.5 | 12.0 | 17.0 |

| DKB-225*250*12/17 | 225.0 | 250.0 | 12.5 | 12.0 | 17.0 |

| DKB-250*275*12/17 | 250.0 | 275.0 | 12.5 | 12.0 | 17.0 |

Material: TPU/Metal

Groove: ISO 6195 Type B

MCW rod wipers are a heavy duty press-fit single lip design. The wiper lip does not protrude from the shoulder of the seal allowing a more compact arrangement when the cylinder is retracted. MCW wipers are available in metric and imperial sizes.

| Part No | (d) ±f7 | (D) H8 | (L) +0.25 |

|---|---|---|---|

| MCW-20*30*7 | 20.0 | 30.0 | 7.0 |

| MCW-25*35*7 | 25.0 | 350 | 7.0 |

| MCW-30*40*7 | 30.0 | 40.0 | 7.0 |

| MCW-32*42*7 | 32.0 | 42.0 | 7.0 |

| MCW-35*50*9 | 35.0 | 50.0 | 9.0 |

| MCW-36*46*7 | 36.0 | 46.0 | 7.0 |

| MCW-40*50*7 | 40.0 | 50.0 | 7.0 |

| MCW-40*55*9 | 40.0 | 55.0 | 9.0 |

| MCW-45*55*5 | 45.0 | 55.0 | 5.0 |

| MCW-45*55*7 | 45.0 | 55.0 | 7.0 |

| MCW-45*60*9 | 45.0 | 60.0 | 9.0 |

| MCW-50*60*5 | 50.0 | 60.0 | 5.0 |

| MCW-50*60*7 | 50.0 | 60.0 | 7.0 |

| MCW-50*65*9 | 50.0 | 65.0 | 9.0 |

| MCW-55*65*5 | 55.0 | 65.0 | 5.0 |

| MCW-56*66*7 | 56.0 | 66.0 | 7.0 |

| MCW-56*68*7 | 56.0 | 68.0 | 7.0 |

| MCW-56*71*9 | 56.0 | 71.0 | 9.0 |

| MCW-60*70*5 | 60.0 | 70.0 | 5.0 |

| MCW-60*74*8 | 60.0 | 74.0 | 8.0 |

| MCW-63*78*9 | 63.0 | 78.0 | 9.0 |

| MCW-65*75*5 | 65.0 | 75.0 | 5.0 |

| MCW-65*79*8 | 65.0 | 79.0 | 8.0 |

| MCW-70*80*5 | 70.0 | 80.0 | 5.0 |

| MCW-70*80*7 | 70.0 | 80.0 | 7.0 |

| MCW-70*84*8 | 70.0 | 84.0 | 8.0 |

| MCW-70*85*7 | 70.0 | 85.0 | 7.0 |

| MCW-75*89*8 | 75.0 | 89.0 | 8.0 |

| MCW-75*90*7.5 | 75.0 | 90.0 | 7.5 |

| MCW-80*90*7 | 80.0 | 90.0 | 7.0 |

| MCW-80*94*8 | 80.0 | 94.0 | 8.0 |

| MCW-80*100*7 | 80.0 | 100.0 | 7.0 |

| MCW-80*100*10 | 80.0 | 100.0 | 10.0 |

| MCW-85*99*8 | 85.0 | 99.0 | 8.0 |

| MCW-90*104*8 | 90.0 | 104.0 | 8.0 |

| MCW-90*105*7 | 90.0 | 105.0 | 7.0 |

| MCW-90*106*8 | 90.0 | 106.0 | 8.0 |

| MCW-90*110*7 | 90.0 | 110.0 | 7.0 |

| MCW-95*109*8 | 95.0 | 109.0 | 8.0 |

| MCW-100*110*7 | 100.0 | 110.0 | 7.0 |

| MCW-100*114*8 | 100.0 | 114.0 | 8.0 |

| MCW-100*116*8 | 100.0 | 116.0 | 8.0 |

| MCW-110*130*8 | 110.0 | 130.0 | 8.0 |

| MCW-110*130*10 | 110.0 | 130.0 | 10.0 |

| MCW-120*136*9 | 120.0 | 136.0 | 9.0 |

| MCW-125*140*9 | 125.0 | 140.0 | 9.0 |

| MCW-130*150*10 | 130.0 | 150.0 | 10.0 |

| Part No | (d) ±f7 | (D) +.001 | (L) +.015 |

|---|---|---|---|

| MCW-0500-25 | 0.500 | 1.000 | 0.250 |

| MCW-0625-31 | 0.625 | 1.125 | 0.312 |

| MCW-0750-31 | 0.750 | 1.250 | 0.312 |

| MCW-0875-31 | 0.875 | 1.375 | 0.312 |

| MCW-1000-31 | 1.000 | 1.500 | 0.312 |

| MCW-1125-31 | 1.125 | 1.625 | 0.312 |

| MCW-1187-21 | 1.187 | 1.623 | 0.218 |

| MCW-1250-31 | 1.250 | 1.750 | 0.312 |

| MCW-1375-31 | 1.375 | 1.875 | 0.312 |

| MCW-1500-31 | 1.500 | 2.000 | 0.312 |

| MCW-1500-31-2 | 1.500 | 2.125 | 0.312 |

| MCW-1562-15 | 1.562 | 1.875 | 0.156 |

| MCW-1625-31 | 1.625 | 2.125 | 0.312 |

| MCW-1750-31 | 1.750 | 2.250 | 0.312 |

| MCW-1750-37 | 1.750 | 2.500 | 0.375 |

| MCW-1875-31 | 1.875 | 2.375 | 0.312 |

| MCW-2000-31 | 2.000 | 2.500 | 0.312 |

| MCW-2000-37 | 2.000 | 2.750 | 0.375 |

| MCW-2000-43 | 2.000 | 2.875 | 0.437 |

| MCW-2125-31 | 2.125 | 2.625 | 0.312 |

| MCW-2125-37 | 2.125 | 2.875 | 0.375 |

| MCW-2250-31 | 2.250 | 2.750 | 0.312 |

| MCW-2250-37 | 2.250 | 3.000 | 0.375 |

| MCW-2375-31 | 2.375 | 2.875 | 0.312 |

| MCW-2500-31 | 2.500 | 3.000 | 0.312 |

| MCW-2500-34 | 2.500 | 3.190 | 0.345 |

| MCW-2625-31 | 2.625 | 3.125 | 0.312 |

| MCW-2625-37 | 2.625 | 3.375 | 0.375 |

| MCW-2750-31 | 2.750 | 3.250 | 0.312 |

| MCW-2750-37 | 2.750 | 3.500 | 0.375 |

| MCW-3000-31 | 3.000 | 3.500 | 0.312 |

| MCW-3000-37 | 3.000 | 3.750 | 0.375 |

| MCW-3125-31 | 3.125 | 3.750 | 0.312 |

| MCW-3250-31 | 3.250 | 3.875 | 0.312 |

| MCW-3500-31 | 3.500 | 4.125 | 0.312 |

| MCW-3500-37 | 3.500 | 4.250 | 0.375 |

| MCW-3625-31 | 3.625 | 4.250 | 0.312 |

| MCW-3750-31 | 3.750 | 4.375 | 0.312 |

| MCW-4000-31 | 4.000 | 4.625 | 0.312 |

| MCW-4250-31 | 4.250 | 4.875 | 0.312 |

| MCW-4500-31 | 4.500 | 5.125 | 0.312 |

| MCW-5000-31 | 5.000 | 5.625 | 0.312 |

| MCW-5500-37 | 5.500 | 6.125 | 0.375 |

| MCW-5500-37 | 5.500 | 6.250 | 0.375 |

| MCW-5750-37 | 5.750 | 6.375 | 0.375 |

| MCW-5750-50 | 5.750 | 6.750 | 0.500 |

| MCW-6000-37 | 6.000 | 6.625 | 0.375 |

| MCW-6500-31 | 6.500 | 7.125 | 0.312 |

| MCW-6750-31 | 6.750 | 7.375 | 0.312 |

| MCW-6750-37 | 6.750 | 7.375 | 0.375 |

| MCW-7000-37 | 7.000 | 7.750 | 0.375 |

| MCW-8000-37 | 8.000 | 8.750 | 0.375 |

| MCW-8500-37 | 8.500 | 9.125 | 0.375 |

Material: NBR/Metal

Groove: ISO 6195 Type B

WPB rod wipers are a heavy duty press-fit single lip design with a rubber lip. The wiper lip does not protrude from the shoulder of the seal allowing a more compact arrangement when the cylinder is retracted. WPB wipers are available in imperial sizes.

| Part No | (d) ±f7 | (D) +.001 | (L) +.015 |

|---|---|---|---|

| WPB-0250-12 | 0.250 | 0.437 | 0.125 |

| WPB-0312-12 | 0.312 | 0.566 | 0.125 |

| WPB-0312-15 | 0.312 | 0.625 | 0.156 |

| WPB-0375-09 | 0.375 | 0.562 | 0.094 |

| WPB-0375-12 | 0.375 | 0.625 | 0.125 |

| WPB-0375-15 | 0.375 | 0.687 | 0.156 |

| WPB-0469-18 | 0.469 | 0.836 | 0.187 |

| WPB-0500-12 | 0.500 | 0.750 | 0.125 |

| WPB-0562-12 | 0.562 | 0.812 | 0.125 |

| WPB-0625-12 | 0.625 | 0.875 | 0.125 |

| WPB-0625-25 | 0.625 | 1.062 | 0.250 |

| WPB-0625-25-2 | 0.625 | 1.250 | 0.250 |

| WPB-0687-12 | 0.687 | 0.937 | 0.125 |

| WPB-0687-18 | 0.687 | 0.999 | 0.187 |

| WPB-0750-12 | 0.750 | 1.000 | 0.125 |

| WPB-0750-18 | 0.750 | 1.125 | 0.187 |

| WPB-0750-25 | 0.750 | 1.250 | 0.250 |

| WPB-0875-12 | 0.875 | 1.125 | 0.125 |

| WPB-0875-18 | 0.875 | 1.250 | 0.187 |

| WPB-0937-12 | 0.937 | 1.187 | 0.125 |

| WPB-1000-12 | 1.000 | 1.250 | 0.125 |

| WPB-1000-18 | 1.000 | 1.375 | 0.187 |

| WPB-1000-18-2 | 1.000 | 1.500 | 0.187 |

| WPB-1000-31 | 1.000 | 1.500 | 0.312 |

| WPB-1000-25 | 1.000 | 1.625 | 0.250 |

| WPB-1062-12 | 1.062 | 1.312 | 0.125 |

| WPB-1062-18 | 1.062 | 1.500 | 0.187 |

| WPB-1125-12 | 1.125 | 1.375 | 0.125 |

| WPB-1125-18 | 1.125 | 1.500 | 0.187 |

| WPB-1125-25 | 1.125 | 1.562 | 0.250 |

| WPB-1125-18-2 | 1.125 | 1.625 | 0.187 |

| WPB-1125-25-2 | 1.125 | 1.625 | 0.250 |

| WPB-1187-18 | 1.187 | 1.562 | 0.187 |

| WPB-1250-12 | 1.250 | 1.500 | 0.125 |

| WPB-1250-25 | 1.250 | 1.752 | 0.250 |

| WPB-1250-18 | 1.250 | 1.687 | 0.187 |

| WPB-1250-18-2 | 1.250 | 1.690 | 0.187 |

| WPB-1250-25-2 | 1.250 | 1.875 | 0.250 |

| WPB-1250-31 | 1.250 | 1.750 | 0.312 |

| WPB-1312-12 | 1.312 | 1.562 | 0.125 |

| WPB-1375-12 | 1.375 | 1.625 | 0.125 |

| WPB-1375-18 | 1.375 | 1.750 | 0.187 |

| WPB-1375-25 | 1.375 | 1.875 | 0.250 |

| WPB-1375-31 | 1.375 | 2.000 | 0.312 |

| WPB-1488-18 | 1.488 | 2.442 | 0.187 |

| WPB-1500-37 | 1.500 | 1.750 | 0.375 |

| WPB-1500-18 | 1.500 | 1.875 | 0.187 |

| WPB-1500-25 | 1.500 | 1.875 | 0.250 |

| WPB-1500-25-2 | 1.500 | 2.000 | 0.250 |

| WPB-1500-31 | 1.500 | 2.000 | 0.312 |

| WPB-1500-25-3 | 1.500 | 2.437 | 0.250 |

| WPB-1562-20 | 1.562 | 2.062 | 0.203 |

| WPB-1625-18 | 1.625 | 2.000 | 0.187 |

| WPB-1625-25 | 1.625 | 2.125 | 0.250 |

| WPB-1750-18 | 1.750 | 2.125 | 0.187 |

| WPB-1750-18-2 | 1.750 | 2.250 | 0.187 |

| WPB-1750-25 | 1.750 | 2.250 | 0.250 |

| WPB-1750-31 | 1.750 | 2.250 | 0.312 |

| WPB-1750-25-2 | 1.750 | 2.375 | 0.250 |

| WPB-1750-37 | 1.750 | 2.437 | 0.375 |

| WPB-1750-25-3 | 1.750 | 2.623 | 0.250 |

| WPB-1875-18 | 1.875 | 2.250 | 0.187 |

| WPB-1875-25 | 1.875 | 2.500 | 0.250 |

| WPB-2000-18 | 2.000 | 2.375 | 0.187 |

| WPB-2000-25 | 2.000 | 2.500 | 0.250 |

| WPB-2000-25 | 2.000 | 2.623 | 0.250 |

| WPB-2000-25-2 | 2.000 | 2.625 | 0.250 |

| WPB-2000-25-3 | 2.000 | 2.686 | 0.250 |

| WPB-2125-18 | 2.125 | 2.500 | 0.187 |

| WPB-2250-18 | 2.250 | 2.625 | 0.187 |

| WPB-2250-25 | 2.250 | 2.625 | 0.250 |

| WPB-2250-25-2 | 2.250 | 2.750 | 0.250 |

| WPB-2375-25 | 2.375 | 2.875 | 0.250 |

| WPB-2500-25 | 2.500 | 3.000 | 0.250 |

| WPB-2500-25-2 | 2.500 | 3.125 | 0.250 |

| WPB-2750-18 | 2.750 | 3.125 | 0.187 |

| WPB-2750-25 | 2.750 | 3.250 | 0.250 |

| WPB-2875-25 | 2.875 | 3.371 | 0.250 |

| WPB-3000-25 | 3.000 | 3.500 | 0.250 |

| WPB-3000-50 | 3.000 | 4.000 | 0.500 |

| WPB-3250-25 | 3.250 | 3.750 | 0.250 |

| WPB-3250-50 | 3.250 | 4.250 | 0.500 |

| WPB-3500-18 | 3.500 | 3.875 | 0.187 |

| WPB-3500-25 | 3.500 | 4.003 | 0.250 |

| WPB-3500-31 | 3.500 | 4.000 | 0.312 |

| WPB-3500-50 | 3.500 | 4.500 | 0.500 |

| WPB-4250-50 | 4.250 | 5.250 | 0.500 |

| WPB-4750-50 | 4.750 | 5.750 | 0.500 |

| WPB-5000-50 | 5.000 | 6.000 | 0.500 |

| WPB-5500-35 | 5.500 | 6.125 | 0.358 |

| WPB-7000-50 | 7.000 | 8.000 | 0.500 |